There are different types of mechanical seals available on the market

Author:admin Date:2023-06-02

Types of Mechanical Seals

Depending on the application, there are different types of mechanical seals available on the market. They range from a cartridge seal to a rotary seal. Each type requires its own set of considerations when choosing. They need to be designed and installed for optimum performance.

In terms of the most basic functions of a mechanical seal, they control friction, leakage and prevent contamination. A mechanical seal also adds to the overall life of a system. It's important to know the right combination of seal faces and lubrication for optimal seal performance. Some of the more popular materials include Carbon-Ceramic, Tungsten Carbide, Stainless Steel and Silicon Carbide.

Mechanical seals are an important component of rotating equipment. They are essential in maintaining the reliability of these devices. They also provide a useful indication of problems that could be harmful to the system. They should be manufactured correctly and installed properly. They also require a good tribological match. In addition, they should be designed to provide the correct degree of pressure. A balanced mechanical seal arrangement is particularly suited to higher operating pressures.

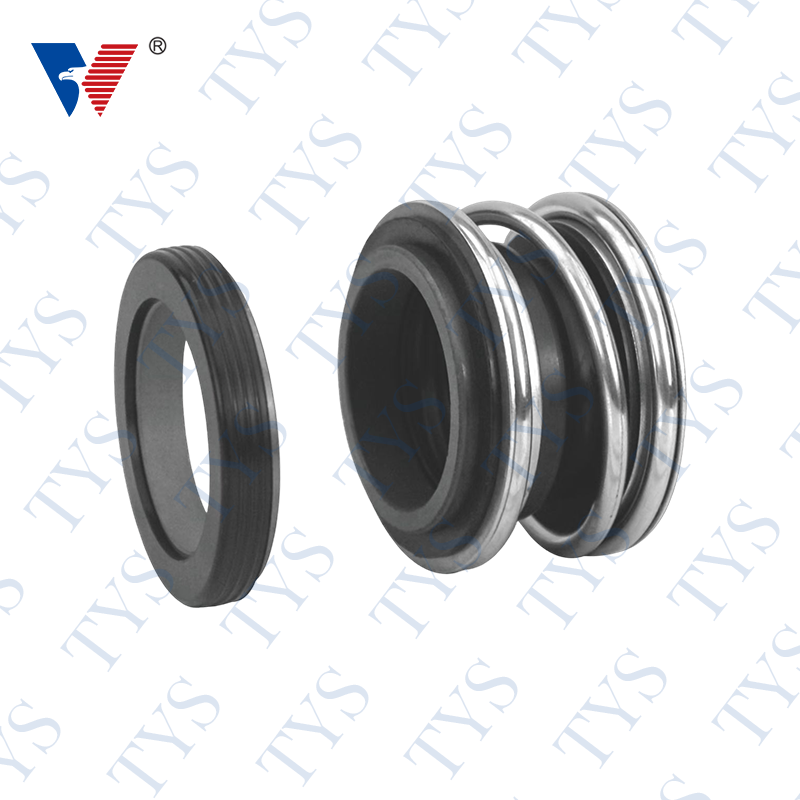

The "Spring Pusher" type mechanical seal assembly is often used for applications in low to moderate temperatures. They have two sub-units, one containing a stationary seat and the other a rotary ring. The assembly is typically lubricated with a barrier fluid, which acts as a cooling agent and penetrates the product in the event of leakage.

Aside from a fluid film, lubrication is a vital part of a mechanical seal. A thin film of process fluid is used to lubricate the sealing faces. This film is typically one micrometer thick. Lubrication also enhances the life of a mechanical seal. Mechanical seals should have the right combination of seal faces, and have a good tribological match.

Some of the more advanced designs can even handle much higher pressures. A balanced mechanical seal arrangement typically operates at 200 PSIG or more. In addition, these types of seals are a good choice for high-pressure, low-lubricity processes.

The API Plan 62 - Quench from External Source is usually used on vertical pumps. It provides a cooling source to prevent the oxidation of process fluid. A throttle bushing may also be used downstream of the secondary seal to warn of its failure.

The API Plan 51 - Quench from Reservoir is used on atmospheric side of the seal. It is generally used on vertical pumps, but it can also be used on other types of pump systems. Aside from the above seal types, there are several other mechanical seal types. In this article, we will discuss the various types of mechanical seals, the advantages and disadvantages of each type, and the factors that should be considered when choosing a seal.

The key to choosing the best mechanical seal is to perform proper installation and maintenance. The right seal type, combination of seal faces, and lubrication will go a long way toward extending the life of your system.

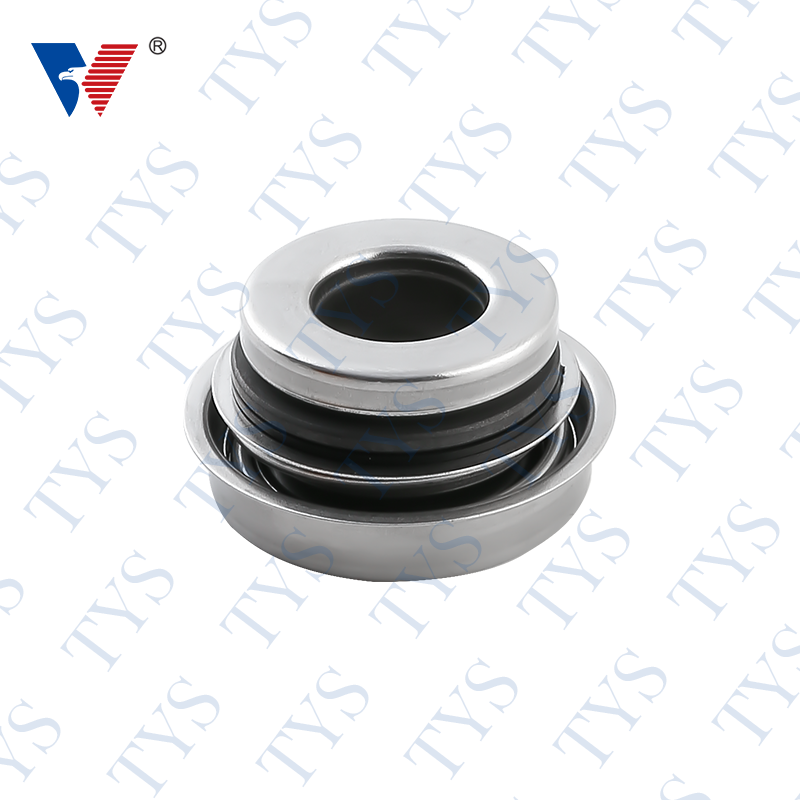

TYSUU4703 Rotary replacement seal pump repair mechanical seal

Sealing chamber pressure: ≤0Mpa~1.2Mpa

Sealing room temperature: -20~80°C (-30~200°C)

Linear speed: ≤12m/sec

Medium: water, oil, sewage with PH value of 6.5-8

Usage: clean water pump, sewage pump, submersible pump, chemical pump and other equipment, used to transport oil,Water and weakly corrosive solutions.

English

English 中文简体

中文简体

.png?imageView2/2/format/jp2)