The Importance of Selecting the Right Industrial Pump Seal

Author:admin Date:2023-04-20

Currently, the industrial pump seal is the most commonly used sealing element in the industrial world. This is due to the fact that it has proved to be highly effective in reducing downtime and energy usage globally. Also, it has been known to reduce industrial emissions. Therefore, it is important to select an appropriate industrial pump seal that can provide a long and efficient service.

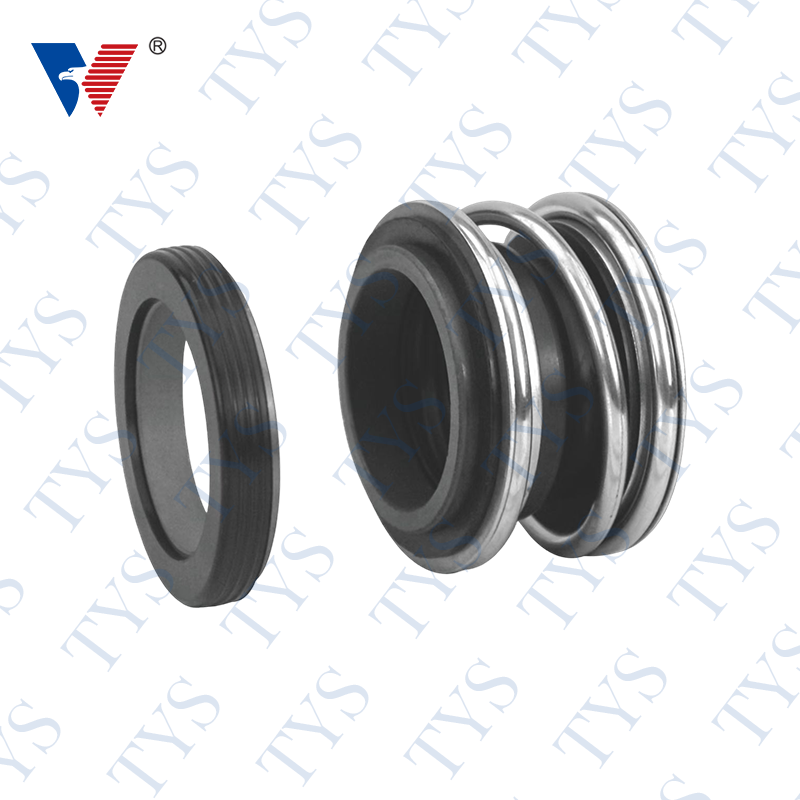

Seals are usually made up of two parts. The stationary part is fixed to the pump casing and the rotary part is attached to the rotating shaft. The stationary part can be a gasket or a static seal. The rotary part can be a spring-loaded element or a rubber seal.

The spring-loaded element can be a spring or an elastomeric bellows. In some cases, it can also be a snap ring that holds the two parts together. Spring-loaded mechanical seals are highly versatile and can be used in most industrial applications. The rotary part of the seal is usually sealed onto the shaft with an O ring. O rings are commonly made from thermoplastic, rubber, or a rubber compound. O rings are generally inexpensive, reliable, and easy to install and remove.

In order to ensure that the mechanical seal functions properly, it needs to be properly installed. An improperly-fitted pump seal can fail very quickly and can damage the product or the pump. It can also expose the product to outside contaminants. In order to avoid such problems, it is important to inspect the pump seal prior to start-up. Moreover, it is also necessary to properly maintain the mechanical seal. This is done through the use of springs and lubricating fluids.

The lubricating fluid used for the mechanical seal has to be compatible with the pumped liquid. However, it should not be used for liquids that are flammable or toxic. Also, it should not be used for liquids with abrasive particulates. It should be cleaned with large volumes of water.

The lubricating liquid provides a thin hydrodynamic film between the seal faces. This film prevents wear and aids heat dissipation. The seal faces can be balanced to allow for higher-pressure sealing. It is important to keep the pressure within a range that will not compromise the seal's life. However, the seal face pressures can change over time and the seal faces can wear. Therefore, the seal face combinations should be carefully chosen.

A good mechanical seal design should consider the type of fluid and temperature. This helps to determine whether or not the seal should be designed with heat-sensitive components. It is also important to keep the seal pressures close to the discharge pressures. Keeping the seal pressure near the discharge pressures will ensure that the seal will have a long and efficient service life.

An industrial pump seal can be used in different industries, such as the oil and gas, power, and chemical industries. It is also used in automobiles and other mechanical equipment.

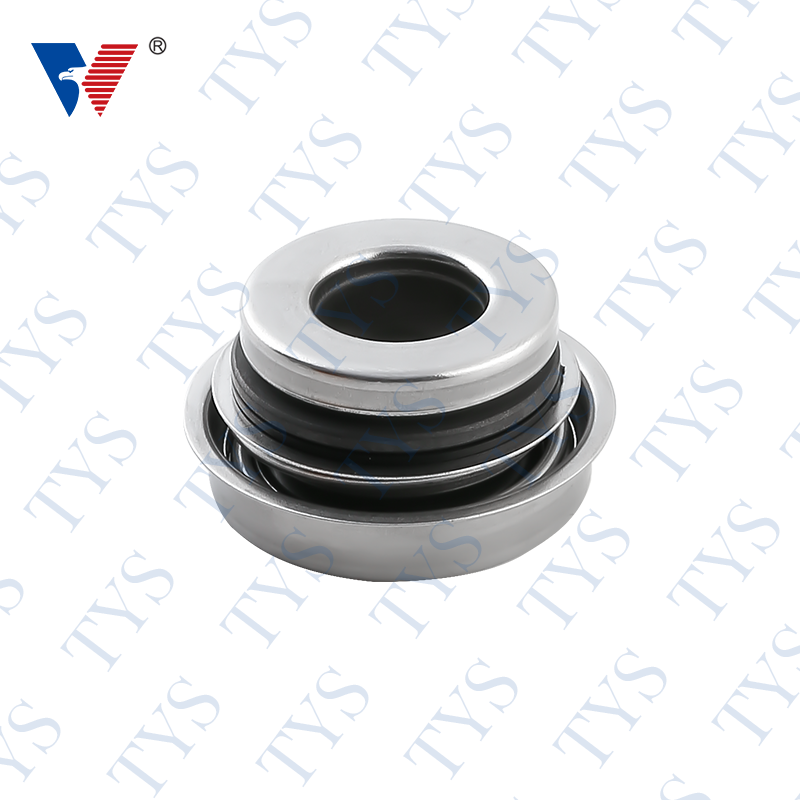

TYS E Series Mechanical Seal

TYS E Series Mechanical Seal

|

MODEL |

d1 |

d3 |

D7 |

L |

L1 |

L4 |

|

TYS E-3/8" |

9.53 |

24 |

22.20 |

22.2 |

16.0 |

6.2 |

|

TYS E-1/2" |

12.70 |

27 |

25.40 |

22.8 |

16.6 |

6.0 |

|

TYS E-5/8" |

15.88 |

31 |

30.10 |

26.5 |

18.3 |

8.5 |

|

TYS E-5/8"H |

15.88 |

31 |

31.75 |

30.1 |

19.8 |

10.3 |

|

TYS E-3/4" |

19.05 |

34 |

34.95 |

28.6 |

18.3 |

9.5 |

|

TYS E-3/4"H |

19.05 |

34 |

34.95 |

30.1 |

19.8 |

10.3 |

|

TYS E-1" |

25.40 |

43 |

41.30 |

31.7 |

20.7 |

11.0 |

English

English 中文简体

中文简体

.png?imageView2/2/format/jp2)