Circulating pumps are often used in commercial applications to move large volumes of superheated steam

Author:admin Date:2023-04-27

Circulation Pump Seal Failures

Having a circulation pump seal fail is no fun. It can lead to unsafe operating conditions inside storage tanks, or worse, a contamination incident. The hazard is especially serious if the system is still new and the pump has not been properly maintained.

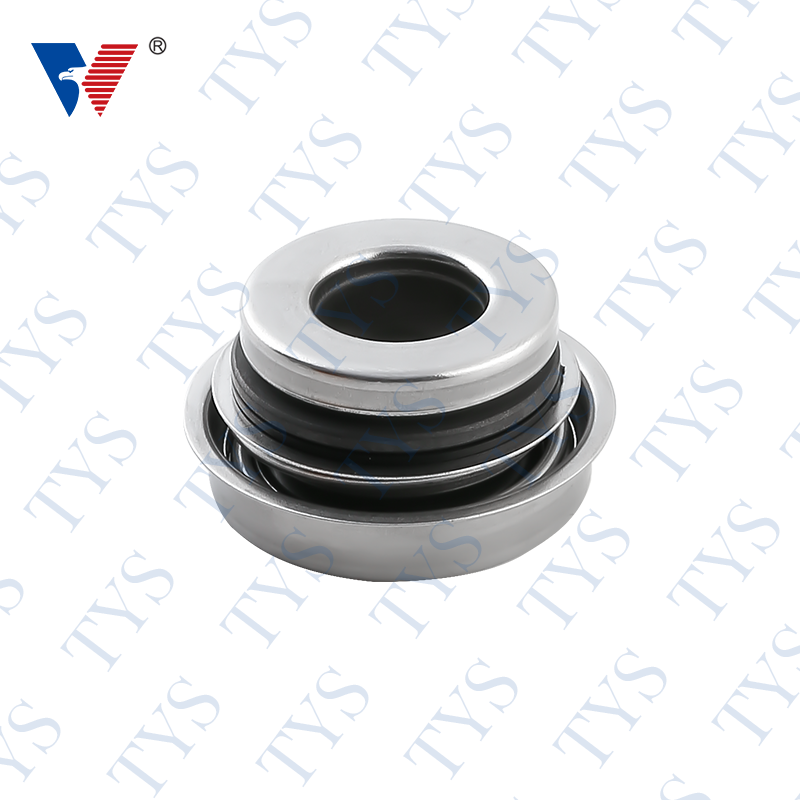

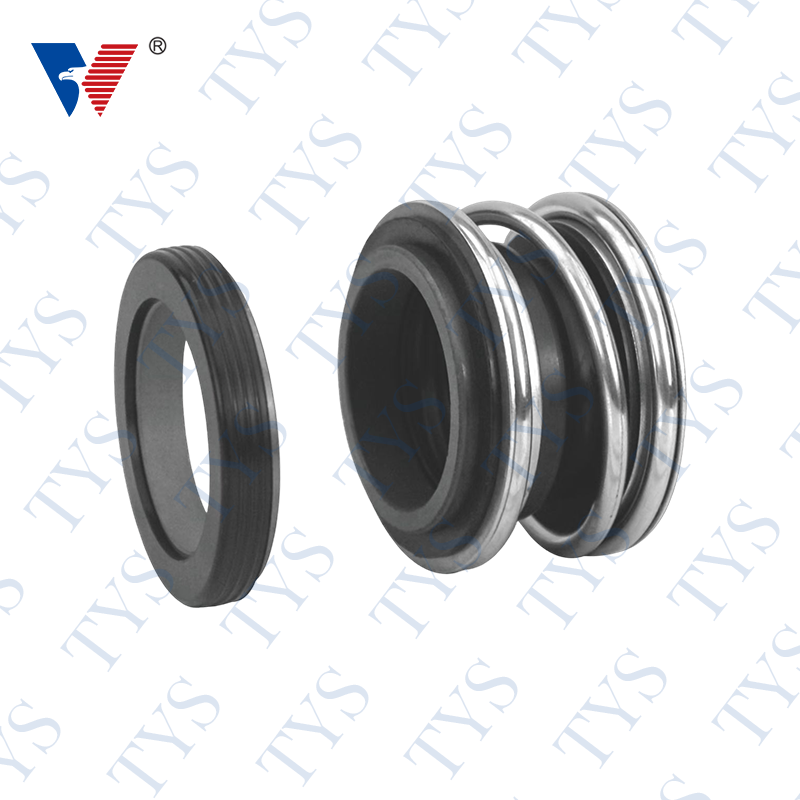

Circulating pumps are often used in commercial applications to move large volumes of superheated steam. They may also be used in home applications. They may be small and sealed or large and two-part. The purpose of a circulation pump is to move contaminated material out of a storage tank. They can be up to many horsepower.

Circulating pumps may also be used to pump water. A worn circulation pump seal can cause water to leak, a problem that can be avoided by periodically cleaning the pump or replacing the seal. They can also be used in home applications where the water pump is isolated from the impeller.

There were many problems in the Bhopal factory, but the MIC pump seal failures were the most serious. They were the immediate source of economic pain. The leaks also impacted the community near the factory. Fortunately, maintenance workers restored the system to service. The community responded in an inconsistent manner. Some responded with questions, while others responded with suspicion.

The workers' union insisted on design changes. These changes were designed to reduce the risk of repeat process releases. This is not a new concept, but the MIC pumps have been plagued by mechanical seal failures. The workers' union emphasized the need for process control to reduce the likelihood of repeat failures.

The most obvious way to reduce the risk of repeat mechanical seal failures is to design the correct seal. Fortunately, there is a simple way to do this. The first step is to determine the cause of a seal failure. This may not be as easy as you think. In some cases, the seal is not the source of the problem, but rather it is a contributing factor. The most likely cause is a worn gasket. When this happens, the seal will not be able to handle the reactivity of the MIC. This is why it is important to properly service circulation pumps.

The new seal had been working for only two days when it suffered a catastrophic failure. This seal, the new mechanical seal, was the first of its kind to be installed at the factory. The seal was a nonmetallic design, which may not have been as strong as a metallic seal. In addition, the seal may not have been the best choice for the application.

English

English 中文简体

中文简体

.png?imageView2/2/format/jp2)