The Importance of Pump Seals

Author:admin Date:2022-08-09

Pump seals have a number of important characteristics that make them an essential component of any pump. These features include multiple leak paths, multiple sealing surfaces, and multiple materials. In most cases, a mechanical pump seal has a single, double, or balanced arrangement, with an outside-mounted spring to prevent leaks. A mechanical pump seal needs to be maintained through the use of springs, metal bellows, or compressed elastomers. Engineered into the design are the loads to be placed on the seal, including the temperature and nature of the fluid.

The mechanical seal used in a pump is generally arranged as an unbalanced, stationary spring assembly. This arrangement helps ensure that springs do not get overly stressed due to high centrifugal forces. There are different types of mechanical seals, each designed for specific operating conditions. The chamber space between the two mechanical seals is filled with a barrier fluid, usually air, and is set to be between 10-15 bars higher than the pump fluid pressure.

Pressure levels of boiling water reactors are 70 bar at 280 degC. Pump seals are able to handle pressures up to 170 bar, and can be used for a variety of applications. A mechanical seal is typically made of a PTFE or elastomeric material, and can withstand a wide range of temperatures. There are many different types of pump seals, but these three are the most common.

Mechanical seals are made up of several discrete parts: a stationary seal and a rotating seal. These components are connected by a spring, which provides tension between the two seal surfaces when the product pressure is low. A secondary seal, such as an o-ring, is typically formed of two sealing surfaces, either single or double. This design is useful in applications where a pump seal is used often, such as in food and beverage processing operations.

Poor installation is one of the leading causes of pump failure. Properly installing each component is critical. Pump seals can be damaged by improper installation, poor lubrication, or components. Failure to properly install a pump can also result in a number of unrelated errors. Proper installation will prevent leakage and ensure a proper pump performance. So, if you suspect a pump seal is leaking, contact a certified technician immediately.

A pump seal is a critical component of a hygienic fluid pump. It prevents leaks between the rotating shaft of the pump and the atmosphere. Improperly selected and fitted pumps require costly repairs and replacement. When a pump seal is leaking or wearing, the fluid inside the pump is exposed to outside contaminants and can compromise the quality of the product. Typical seal types include o-rings and mechanical seals.

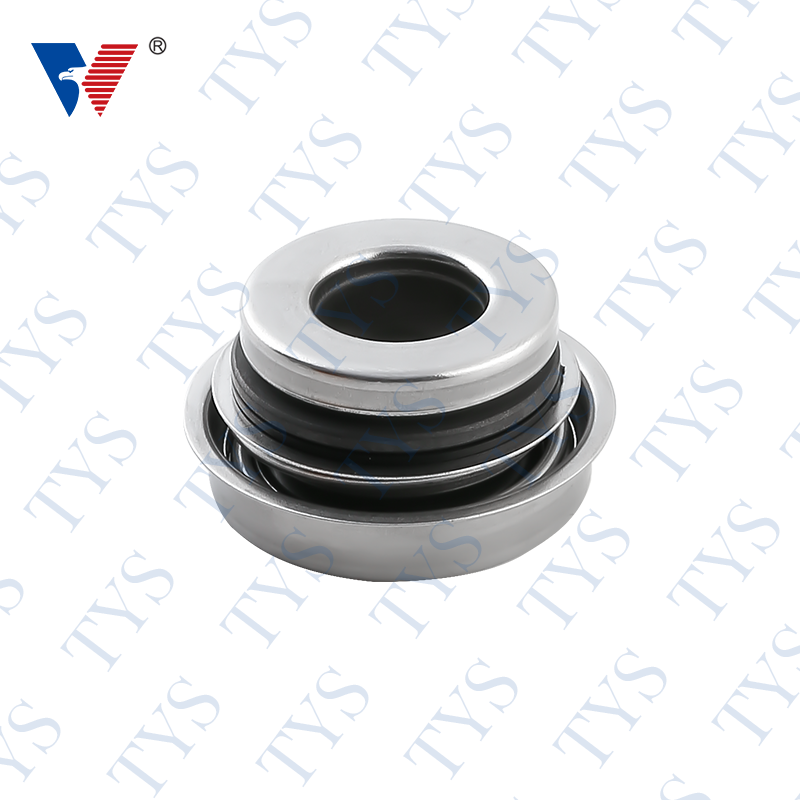

TYS 1008 Pump seal supplier bellow Mechanical Seal MG9 MG912 for water pump

Annular Seal Pressure:≤OMpa~ 1.2Mpa

Annular Seal Temperature: - 20~80°C(-30~200°C)

Rotation speed:≤12m/sec

Medium: Water, Oiland PH numerical value of waste water is 6.5- -8

Used in clean water pumps,in-Line pumps and general industrial pumps

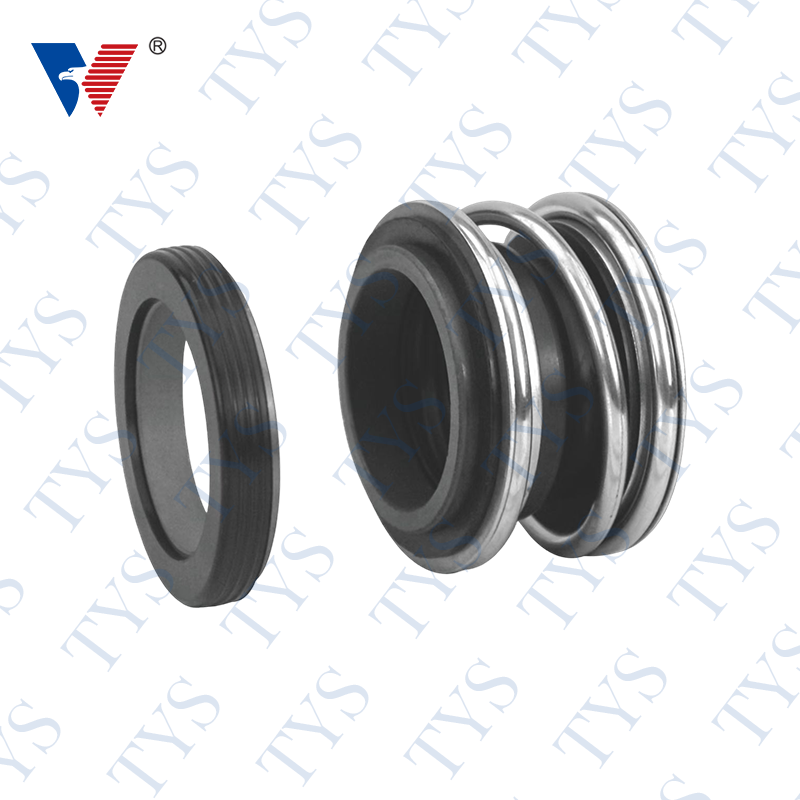

- Stationary Ring(Ceramic/SiC/TC)

- Rotary Ring(Carbon/SiC)

- Secondary Seal(NBR/EPDMVITON)

- Retainer(SUS304)

- Spring(SUS304)

- Spring Holder(SUS304)

-

MODEL

d1

d3

D7

L

L28

L2

TYS1008-8

8

20

21

20

6

5

TYS1008-10

10

21

22

20

6

5

TYS1008- 12

12

22

26

23

6.5

6

TYS1008- 14

14

24.5

28

25

6.5

6

TYS1008-16

16

26.5

28

25

6.5

6

TYS1008-18

18

32

33

27

7.5

6

TYS1008-20

20

34

35

29

7.5

6

TYS1008- -22

22

34

37

29

7.5

6

TYS1008-25

25

39

40

31

7.5

6

TYS1008- -28

28

44

43

34

7.5

6

TYS 1008- -30

30

44

45

34

7.5

6

TYS1008-35

35

49

50

36

7.5

6

TYS1008-40

40

56

58

39

9

8

TYS1008- 45

45

61

63

39

9

8

TYS1008-50

50

67

70

40

9.5

8

TYS1008-55

55

72

75

46

11

8

TYS1 008-60

60

77

80

49

11

9

TYS1008-14d

14

24.5

26

25

6.5

6

TYS1008-17

17

32

35

27

7.5

6

English

English 中文简体

中文简体

.png?imageView2/2/format/jp2)