Submersible Pump Seal Basics

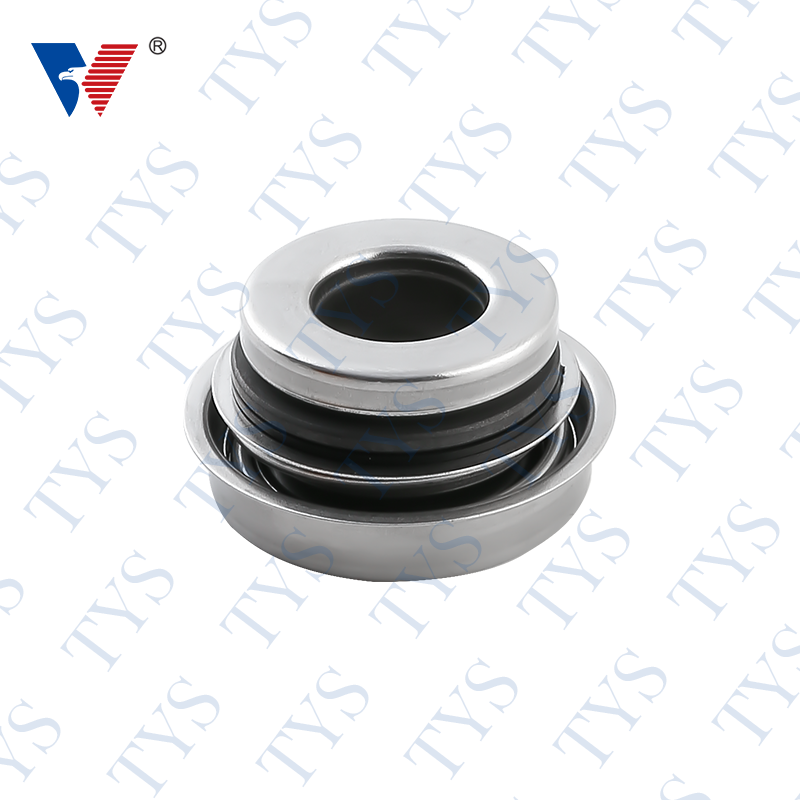

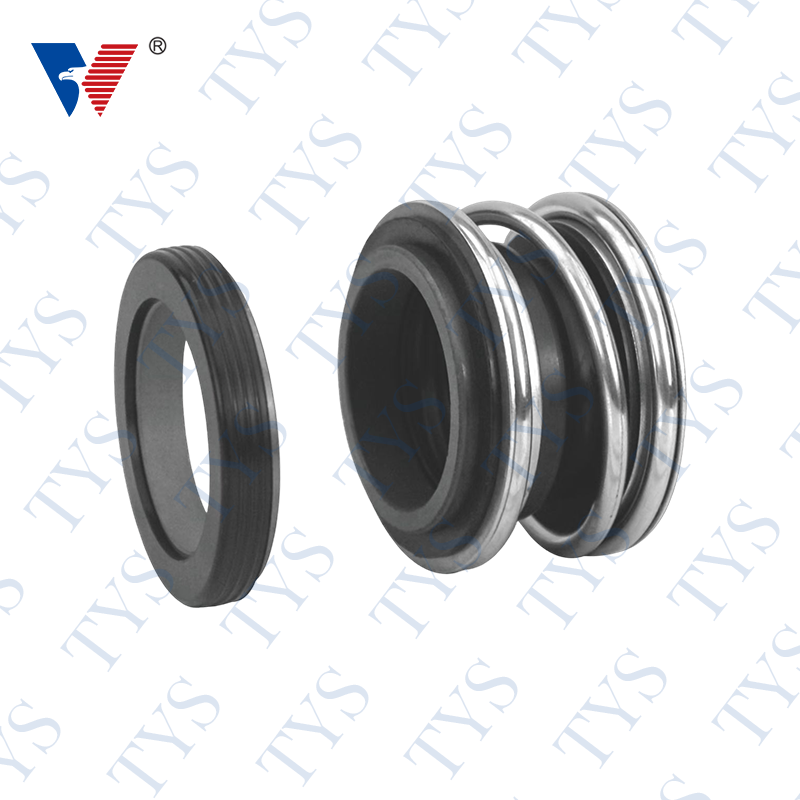

TYS 1006 Mechanical seal John crane type 2100K pump shaft seal

Operating Limits

Annular Seal Pressure:≤OMpa~1.2Mpa

Annular Seal Temperature: -20~80℃(-30~200℃)

Rotation speed:≤12m/sec

Medium: water, oil and sewage with PH value of 6.5-8

Mainly used in various centrifugal pumps, pipeline pumps, industrial pumps, vortex pumps, etc.

- Single end face

- Single bullet

- Unbalanced seal

- Rubber bellows

- Any rotation

- Static Ring (Silicon Carbide/Tungsten Carbide)

- Moving ring (graphite/silicon carbide)

- Auxiliary sealing (nitrile rubber/ethylene propylene rubber/fluorine rubber/hydrogenated nitrile)

- Transmission sleeve (stainless steel)

- Spring (stainless steel)

- Spring seat (stainless steel)

|

MODEL |

d1 |

d3 |

D7 |

L |

L28 |

L2 |

|

TYS1006-12 |

12 |

28 |

26 |

23 |

6.5 |

5.0 |

|

TYS1006-14 |

14 |

32 |

28 |

25 |

6.5 |

6.0 |

|

TYS1006-16 |

16 |

32 |

27 |

25 |

6.5 |

6.0 |

|

TYS1006-18 |

18 |

39 |

33 |

27 |

7.5 |

6.0 |

|

TYS1 006-20 |

20 |

39 |

35 |

29 |

7.5 |

6.0 |

|

TYS1006-25 |

25 |

46 |

40 |

31 |

7.5 |

6.0 |

|

TYS1006-28 |

28 |

51 |

43 |

34 |

7.5 |

6.0 |

|

TYS1006-30 |

30 |

51 |

45 |

34 |

7.5 |

6.0 |

|

TYS1006-35 |

35 |

59 |

50 |

36 |

7.5 |

6.0 |

|

TYS1006-40 |

40 |

66 |

58 |

39 |

9 |

8.0 |

|

TYS1006-45 |

45 |

72 |

63 |

39 |

9 |

8.0 |

|

TYS1006-50 |

50 |

77 |

70 |

40 |

9.5 |

8.0 |

|

TYS1006-55 |

55 |

84 |

75 |

46 |

11 |

8.5 |

|

TYS1006-60 |

60 |

88 |

80 |

49 |

11 |

9.0 |

|

TYS1006-65 |

65 |

97 |

85 |

51 |

11 |

9.0 |

|

TYS1006-70 |

70 |

104 |

92 |

51 |

11 .3 |

9.0 |

|

TYS1006-75 |

75 |

110 |

97 |

51 |

11 .3 |

9.0 |

|

TYS1006-80 |

80 |

116 |

105 |

52 |

12 |

10 |

|

TYS1006-85 |

85 |

124 |

110 |

55 |

14 |

10 |

|

TYS1006-90 |

90 |

131 |

115 |

59 |

14 |

10 |

|

TYS1006-95 |

95 |

136 |

120 |

60 |

14 |

10 |

|

TYS1006-100 |

100 |

141 |

125 |

61 |

14 |

10 |

|

TYS1006-110 |

110 |

150 |

140 |

61 |

14 |

10 |

|

TYS1006-120 |

120 |

160 |

150 |

61 |

14 |

10 |

|

TYS1006-12d |

12 |

28 |

23 |

21 |

6.5 |

5.5 |

|

TYS1006-14d |

14 |

32 |

25 |

23 |

6.5 |

5.5 |

|

MODEL |

d1 |

d3 |

D7 |

L |

L28 |

L2 |

|

2100-1/2" |

12.70 |

25 |

25.40 |

15 |

6.50 |

7.90 |

|

2100-5/8" |

15.88 |

26 |

31.75 |

15 |

8.70 |

10.30 |

|

2100-3/4" |

19.05 |

32 |

34.93 |

20 |

8.70 |

10.30 |

|

2100- 1" |

25.40 |

39 |

41.28 |

20 |

9.50 |

11.10 |

|

2100-1 1/8" |

28.58 |

42 |

44. .45 |

26 |

9.50 |

11.10 |

|

2100-1 3/8" |

34.93 |

49 |

50.80 |

26 |

9.50 |

11.10 |

|

2100-1 1/2" |

37.10 |

54 |

53.98 |

30 |

9.50 |

11.10 |

|

2100-1 3/4" |

44.45 |

61 |

63.50 |

30 |

11.10 |

12.70 |

|

2100-2" |

50.80 |

66 |

69.85 |

30 |

11.10 |

12.70 |

|

2100-2 1/8" |

53.98 |

69 |

76.20 |

30 |

12.70 |

14.30 |

|

2100-2 3/8" |

60.33 |

80 |

82.55 |

33 |

12.70 |

14.30 |

|

2100-2 1/2" |

63.50 |

83 |

85.73 |

33 |

12.70 |

14.30 |

|

2100-2 5/8" |

66.68 |

88 |

85.73 |

33 |

14.30 |

15.90 |

|

2100-2 3/4" |

69.85 |

89 |

88.90 |

33 |

14.30 |

15.90 |

|

2100-3" |

76.20 |

99 |

98.43 |

40 |

14.30 |

15.90 |

|

2100-3 1/8" |

79.38 |

103 |

101.60 |

40 |

18.00 |

19.80 |

|

2100-3 1/4" |

82.55 |

104 |

104.78 |

40 |

18.00 |

19.80 |

|

2100-3 3/8" |

85.73 |

108 |

107.95 |

40 |

18.00 |

19.80 |

|

2100-3 1/2" |

88.90 |

112 |

111.13 |

40 |

18.00 |

19.80 |

|

2100-3 5/8" |

92.08 |

114 |

114.30 |

40 |

18.00 |

19.80 |

|

2100-3 3/4" |

95.25 |

118 |

117.48 |

40 |

18.00 |

19.80 |

|

2100-4" |

101.6 |

124 |

123.83 |

40 |

18.00 |

19.80 |

|

MODEL |

d1 |

d3 |

D7 |

L4 |

L2 |

L1 |

L12 |

L13 |

|

2100-12 |

12 |

22 |

23 |

6 |

5 |

15 |

26.5 |

34 |

|

2100-14 |

14 |

24 |

25 |

6 |

5 |

15 |

29 |

34 |

|

2100-16 |

16 |

26 |

27 |

6 |

5 |

15 |

29 |

34 |

|

2100-18 |

18 |

32 |

33 |

6 |

5 |

20 |

31.5 |

39 |

|

2100-20 |

20 |

34 |

35 |

6 |

5 |

20 |

31.5 |

39 |

|

2100-25 |

25 |

39 |

40 |

6 |

5 |

20 |

34 |

44 |

|

2100-28 |

28 |

42 |

43 |

6 |

5 |

26 |

36.5 |

44 |

|

2100-30 |

30 |

44 |

45 |

7 |

5 |

26 |

35.5 |

43 |

|

2100-35 |

35 |

49 |

50 |

8 |

6 |

26 |

34.5 |

47 |

|

2100-40 |

40 |

56 |

58 |

8 |

6 |

30 |

37 |

47 |

|

2100-45 |

45 |

61 |

63 |

8 |

6 |

30 |

37 |

52 |

|

2100-50 |

50 |

66 |

70 |

10 |

8 |

30 |

37.5 |

50 |

|

2100-55 |

55 |

71 |

75 |

10 |

8 |

30 |

37.5 |

60 |

|

2100-60 |

60 |

80 |

80 |

12 |

10 |

33 |

40.5 |

58 |

|

2100-65 |

65 |

85 |

85 |

12 |

10 |

33 |

40.5 |

68 |

|

2100-70 |

70 |

90 |

92 |

12 |

10 |

33 |

48 |

68 |

|

2100-75 |

75 |

99 |

97 |

12 |

10 |

40 |

48 |

68 |

|

2100-80 |

80 |

104 |

105 |

14 |

12 |

40 |

47.5 |

77.5 |

|

2100-85 |

85 |

109 |

110 |

14 |

12 |

40 |

47.5 |

77.5 |

|

2100-90 |

90 |

114 |

115 |

14 |

12 |

40 |

52.5 |

77.5 |

|

2100-95 |

95 |

119 |

120 |

14 |

12 |

40 |

52.5 |

77.5 |

|

2100-100 |

100 |

124 |

125 |

14 |

12 |

40 |

52.5 |

77.5 |

English

English 中文简体

中文简体

.png?imageView2/2/format/jp2)