What Is a Rubber Seal?

Author:admin Date:2022-08-18

A Rubber Seal is a mechanical component with a certain type of compression set. A compression set occurs when a rubber compound experiences repeated deformation. The amount of deformation required to reach a specified state is called a fatigue life. This is determined by vulcanization methods, and varies from type to type. Axisymmetric and axial seals are examples of compression sets. They are also known as "o-rings."

A rubber seal is made of rubber that is typically regarded as a durable material. While the material is durable, temperature can have a dramatic impact on its performance. Low temperatures can weaken the strength of rubber compounds, resulting in leak paths in the seal. This damage may not occur immediately, but may take years before the material fails. During this time, the pressure and temperature in a sealed product will be higher than normal. Once the pressure and temperature decreases, however, the strength of the seal is restored, which will ensure that the product is fully functional.

The temperature range in which a Rubber Seal is intended is very important. It should be noted that silicone, fluorocarbon, and perfluoroelastomer have excellent heat resistance. However, high temperatures can cause the material to deform permanently. Overly cold temperatures can cause shrinkage, which can lead to leakage due to the loss of seal contact or insufficient compressive force. To avoid these problems, it is best to choose the right material for the job.

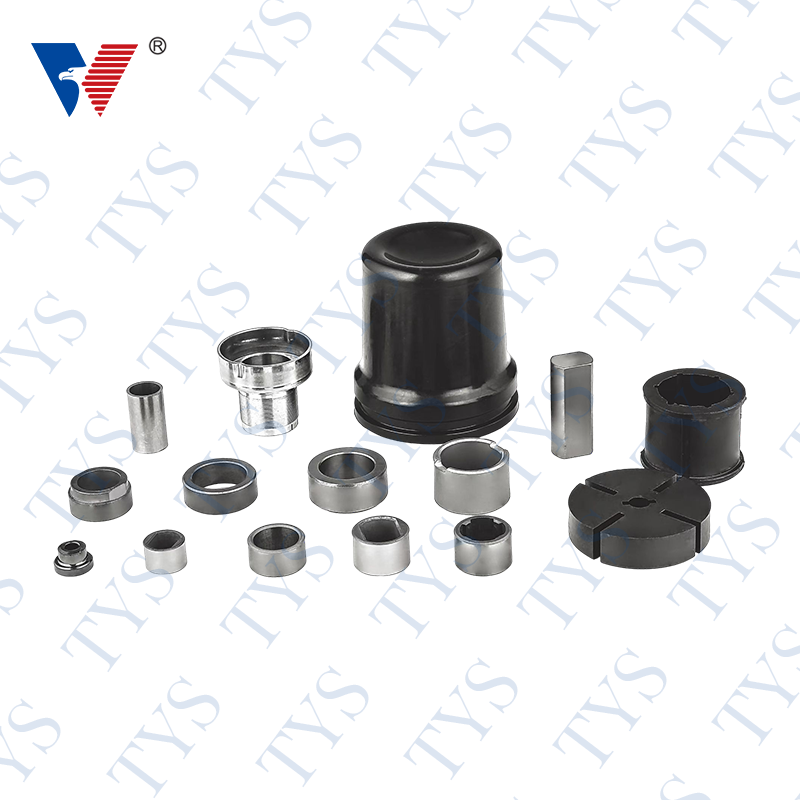

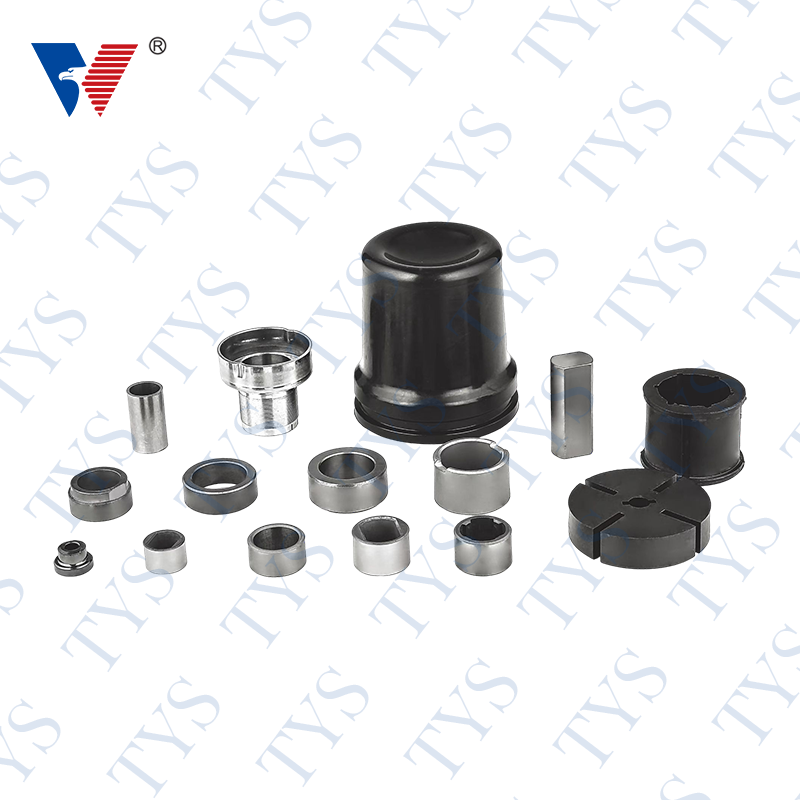

The materials that make up a Rubber Seal vary based on their specific function and environment. Often, a rubber seal is reinforced with a metal core to increase its rigidity. A Rubber Seal is a vital component of many industrial machinery applications. The use of rubber oil in hydraulic cylinders is one example. The seal prevents pressurization loss and contamination. For the most part, rubber seals are made of resilient synthetic rubber materials. One popular synthetic rubber material is Teflon, which has exceptional strength, heat resistance, and corrosion resistance.

An O-ring must compress between the two mating surfaces of the gland. This compression forces the O-ring to form a tight seal between the two surfaces. The cross section of the O-ring must be greater than the gland depth, because the O-ring seal is exerted equally on both ends of the gland. Choosing the wrong O-ring can lead to overpacking of the gland or not providing a tight seal. You can choose the right size for your specific needs.

The properties of a Rubber Gasket vary from one type to another, and they are used in a wide range of applications. The EPDM gasket seal, for instance, fills the space between two sections of a substrate. This flexible gasket is used in a number of applications, including automotive components, as well as medical devices, where airtight sealing is crucial. So how can you find the right one for your needs? Find out now by visiting the website of a reputable rubber gasket manufacturer.

English

English 中文简体

中文简体

.png)