Pump mechanical seals are found in hydraulic centrifugal pumps

Author:admin Date:2022-12-01

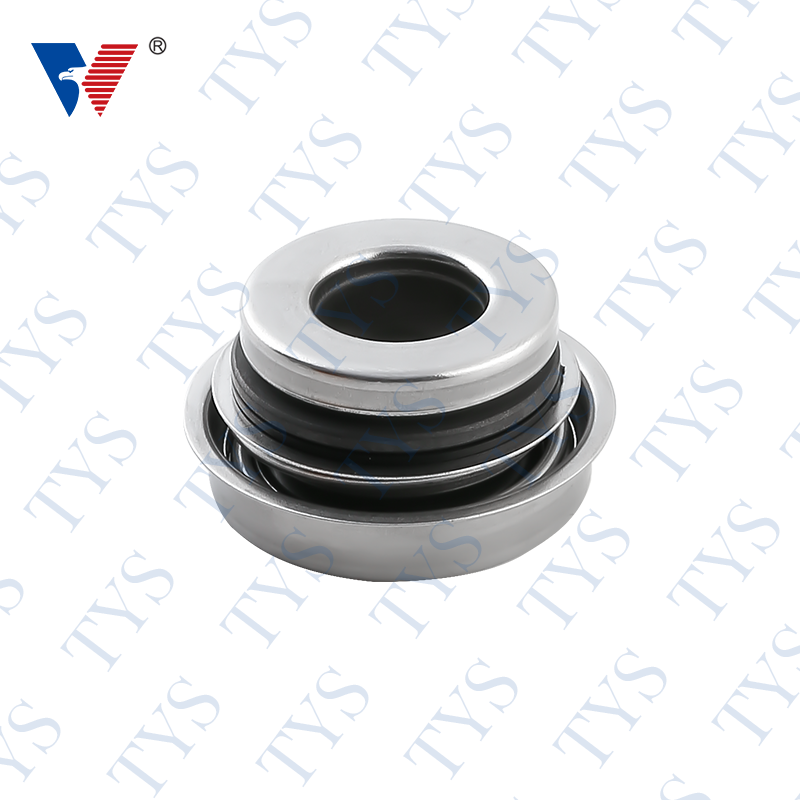

Pump Mechanical Seal

Generally, pump mechanical seals are found in hydraulic centrifugal pumps. Usually, these seals consist of a rotary ring connected to a shaft. The rotating ring is processed into a flat plane by applying a lubricating liquid. The lubricating liquid is injected into the seal chamber. The lubricant forms a thin hydrodynamic film between the seal faces. This film aids in cooling and lubrication, reducing the wear of the seal.

Mechanical seals are used to prevent leaks, control friction, and increase operational safety. They can also help maintain the fluid's position in the pump casing. In addition, they reduce heat generation and reduce maintenance costs. Mechanical seals are available in hundreds of different designs, and some of them are simple and inexpensive. Others are more complex.

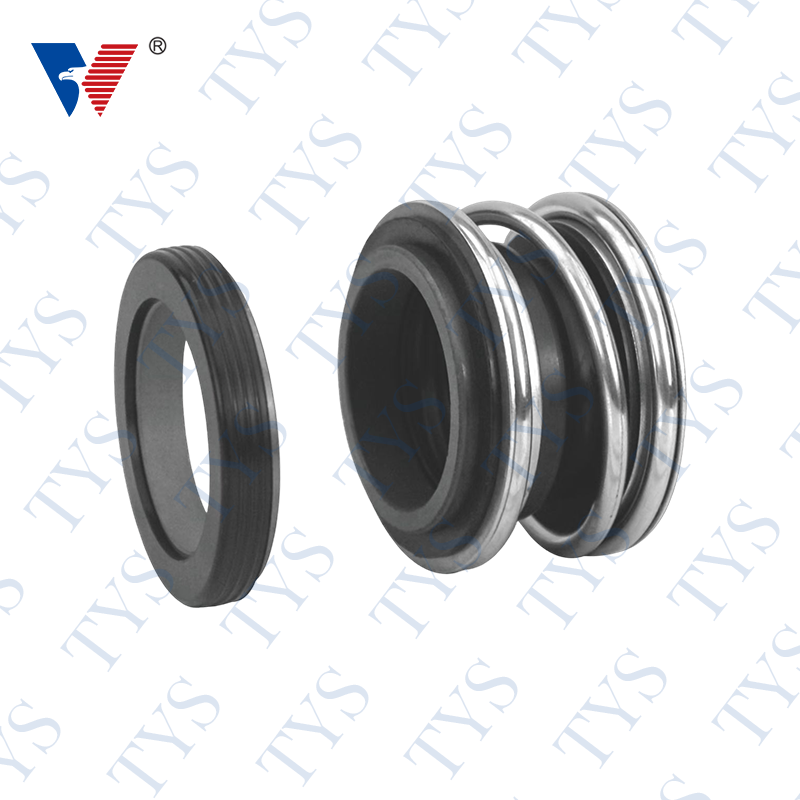

The rotary ring of a pump mechanical seal is often made of carbon. This ring can be damaged by excessive heat, abrasive particles, and dirt. In addition, the lubricant used for sealing can be washed away by the pump operation. This can be a problem, especially in special applications.

To avoid the problem, the seal support system should be capable of pumping the fluid. However, this does not mean that the pump will be able to handle the pumped liquid. Mechanical packing was used to seal pumps before mechanical seals. The packing consists of fibrous materials that were usually impregnated with lubricants. The packing was also placed in direct contact with the shaft.

During pump operation, the lubricant can be washed away, resulting in damage to the secondary seals. To avoid this problem, the pump needs to be properly lubricated. The lubricant should be water soluble. The water can also corrode the pump adapter.

Mechanical seals also suffer from heat damage. The pump faces become very hot when there is no liquid in the chamber. Therefore, they need to be cooled. The best way to do this is to provide medium pressure steam in the seal chamber jacket. This keeps the lubricant between the mating seal faces from vaporizing. However, some mechanical seals are not required to be cooled.

Another factor that can cause a mechanical seal to fail is the misalignment of the shaft. This can result in vibrations, and can cause the seal to leak. In addition, an imbalance of the shaft and bearings can also cause mechanical seal failure.

In order to reduce this issue, you should make sure that the shaft and the housing are corrosion-free. You may also need to drill a passageway at a 15- to 45-degree angle from the top of the seal chamber. This passageway is used to vent the vapors. Normally, this opening is oriented downward.

The secondary seal is also called a V-Ring. Usually, these seals are made of elastomer and need to be pliable. You should check the wear pattern of the secondary seal faces. The wear pattern should be smooth and slightly shiny. This wear pattern should be consistent with the other seal faces.

English

English 中文简体

中文简体

.png?imageView2/2/format/jp2)