Installation of a Vertical Pump Seal

Author:admin Date:2023-03-31

Installation of a Vertical Pump Seal

During the installation process of a vertical pump seal, it is important to consider the effects that pump equipment will have on seal chamber pressure. This includes the pressure difference between the seal chamber and the pump suction and the pressure difference between the seal chamber and the discharge. This can affect the lifespan of the seal and cause problems for the supply system.

The mechanical seal is located behind the impeller on the pump shaft. It is composed of pairs of optically flat faces that are only in contact when the pump is at rest. When the pump is operating, the fluid travels from the high-pressure side to the low-pressure side. The lubricating liquid provides a thin hydrodynamic film between the seal faces that aids heat dissipation.

Mechanical seals are used to prevent liquid from leaking between the rotating and stationary areas of a pump. The process fluid is circulated from the discharge to the seal chamber. It is then circulated back to the pump's suction. This is done to keep the seal from being damaged and to keep unwanted vapors from leaking into the atmosphere.

The primary seal is a spring-loaded vertical bearing that prevents process leakage between the rotating and stationary areas. The primary seal is pushed together by the hydraulic force of the sealed fluid. This seal is the most basic seal design. It is composed of two optically flat faces that attach to the shaft. A bleed bushing is used to remove solids from the seal chamber. This bushing acts as a journal bearing to the center shaft before the seal enters the seal chamber.

The sealing faces of a vertical pump seal are cooled with coolant and flush fluid. The flush fluid must be a moderate temperature and non-polymerizing fluid. The flush fluid may be delivered from an external source or may be delivered from the reservoir within the seal support system. The flush fluid must be sufficient to remove heat from the mechanical seal chamber and to maintain a flush flow rate for the pump.

In the past, a vertical slurry pump may have been operated at atmospheric pressure. This pressure caused problems for the seal because of the high temperature and pressure. However, modern cartridge seal designs are more forgiving. The seal's faces are lightly loaded with the process fluid, which reduces the power consumed by the seal. The design also prevents the pump sleeve and the seal chamber from being damaged.

In order to increase seal life, it is important to choose the correct seal technology. This includes selecting the seal face material that will be most suitable for your application. In addition, it is also important to select the proper seal chamber pressure. This can prevent long dry running at start-up.

A cartridge seal is a pre-assembled seal that can be easily installed. It is also a faster and more efficient installation method than gland packing. It has inboard springs that can be easily adjusted as the seal faces wear.

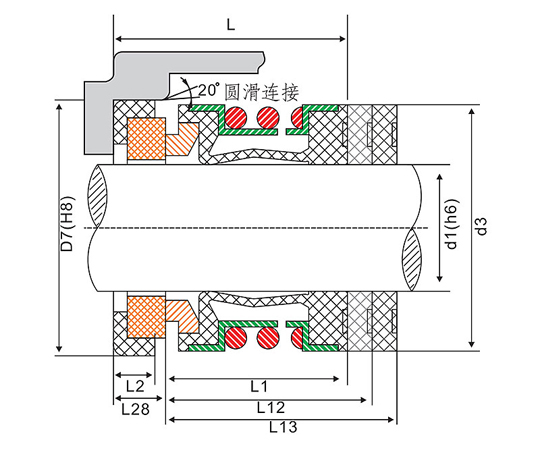

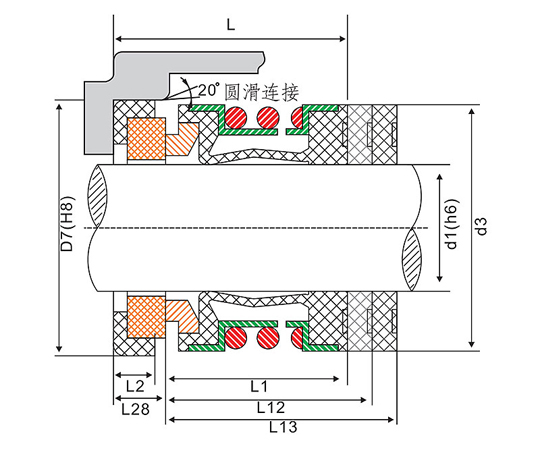

TYS 1006 Mechanical seal John crane type 2100K pump shaft seal

TYS 1006 Mechanical seal John crane type 2100K pump shaft seal

English

English 中文简体

中文简体

.png)