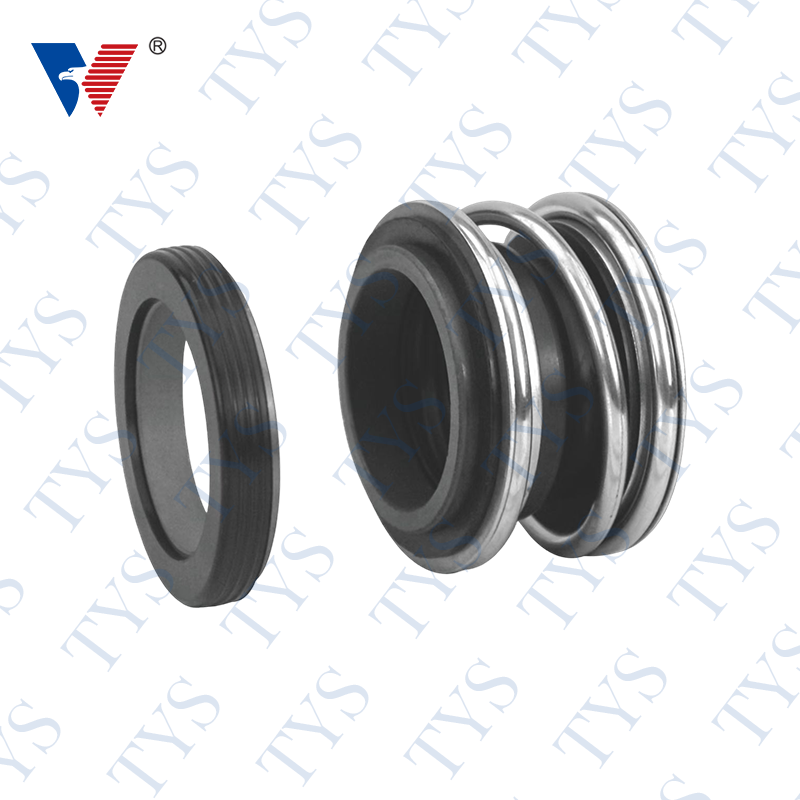

A Pump Mechanical Seal plays a crucial role in the flow of pumped fluid. It ensures that the pumping fluid does not come into contact with the seal's metal parts. There are two types of pump mechanical seals: outside seals and pusher seals. Outside seals are typically non-metallic. They are designed with a rotary portion that is located outside the seal chamber. They compensate for the movement of the shaft and face wear.

0.010"

A 0.010" pump mechanical seal is used to stop leaking liquids from a pump. A standard solution uses acrylonitrile butadiene rubber (NBR) or a high-temperature solution uses steel/carbon and fluoro rubber (FKM). Some companies use magnetic couplings. These are safer and require less maintenance than mechanical seals.

0.020"

If your pump has a 0.020" mechanical seal, you should know what to do to ensure a smooth installation. It is important to lubricate the seal seat with soap and water or ethylene glycol before slipping the impeller over the seal seat. If the seal is a bit worn, replace the ring. Once the ring is replaced, inspect the rear bearing housing and oil seal for wear. After removing the ring, lubricate the mechanical seal seat with ethylene glycol or a soap and water solution.

0.040"

If you need to replace a 0.040" pump mechanical seal, you have a few choices. Typically, this type of seal is made up of three parts, with the stationary part fitted to the pump housing using a static seal. If the pump's pump housing is made of other material, the stationary part may be sealed with an o-ring or gasket.

0.050"

There are several different types of mechanical seals available for pumps. One type is a static seal, made of NBR or acrylonitrile butadiene rubber, while another type is made of steel/carbon and fluoro rubber (FKM). Regardless of the type, the main goal of mechanical seals is to prevent the product from leaking. To achieve this, a mechanical seal is designed with multiple sealing points and wedges. The faces of the mechanical seal must be clean, lubricated, and square to the shaft. This can be achieved by using a barrier fluid such as water. The barrier fluid helps maintain the seal by flushing out the seal, lubricating the shaft, and cooling the seal.

0.060"

The PSS 4 split seal is an advanced technology semi-cartridge design. This unique design features intrinsic joint alignment technology, which helps to reduce downtime and installation time. This seal also features unique setting tabs that help to position the rotating face during installation, removing the need for manual marking and positioning of the seal. Additionally, the PSS 4 split seal accommodates the runout of mixer equipment.

0.080"

When choosing the right pump mechanical seal for your application, you'll want to make sure you choose the right one for the application. The right type of seal will not only be easy to install, but it will also help improve reliability and extend the life of your pump. To find the right seal for your application, consult with an expert.

0.030"

The 0.030" pump mechanical seal is a basic design, consisting of three main sealing points: the pump shaft and the pump housing. The stationary part of the seal is fitted to the pump housing using a static seal and may be fitted with an o-ring or gasket. The seal consists of a series of packing elements that physically stuff the gap. This prevents leakage of the process fluid between the rotating and stationary areas.

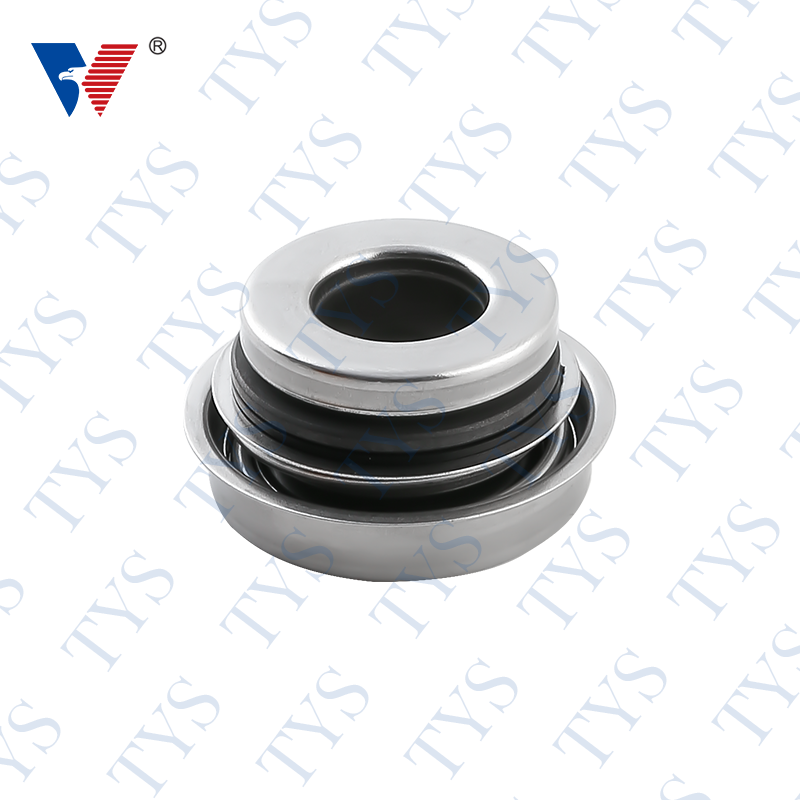

TYS1009、MG1、MG12、MG13 Rubber bellows mechanical seal professional mechanical seal supplier

|

MODEL

|

d1

|

d3

|

D7

|

L

|

L28

|

MG1

|

MG12

|

MG13

|

|

TYS1009-12

|

12

|

25

|

26

|

21.5

|

6.5

|

/

|

/

|

/

|

|

TYS1009-14

|

14

|

28.5

|

28

|

23.5

|

6.5

|

/

|

/

|

/

|

|

TYS1009-16

|

16

|

28.5

|

27

|

23.5

|

6.5

|

17.0

|

28.5

|

33.5

|

|

TYS1009-18

|

18

|

32

|

33

|

27

|

6.5

|

19.5

|

30.0

|

37.5

|

|

TYS1009-20

|

20

|

37

|

35

|

29

|

6.5

|

21.5

|

30.0

|

37.5

|

|

TYS1009-22

|

22

|

37

|

37

|

29

|

7.5

|

21.5

|

30.0

|

37.5

|

|

TYS1009-25

|

25

|

42.5

|

40

|

31

|

7.5

|

23.0

|

32.5

|

42.5

|

|

TYS1009-28

|

28

|

49

|

43

|

34

|

7.5

|

26.5

|

35.0

|

42.5

|

|

TYS1009-30

|

30

|

49

|

45

|

34

|

7.5

|

26.5

|

35.0

|

42.5.

|

|

TYS1009-35

|

35

|

57

|

50

|

36

|

9

|

28.5

|

35.0

|

47.5

|

|

TYS1009-40

|

40

|

62

|

58

|

36

|

9

|

30.0

|

36.0

|

46.0

|

|

TYS1009-45

|

45

|

68

|

63

|

39

|

9.5

|

30.0

|

36.0

|

51.0

|

|

TYS1009-50

|

50

|

74

|

70

|

39

|

11

|

30.0

|

38.0

|

50.5.

|

|

TYS1009-55

|

55

|

81

|

75

|

46

|

11

|

35.0

|

36.5

|

59.0

|

|

TYS1009-60

|

60

|

85.5

|

80

|

49

|

11

|

38.0

|

41.5

|

59.0

|

|

TYS1009-65

|

65

|

93.5

|

85

|

51

|

11.3

|

40.0

|

41.5

|

69.0

|

|

TYS1009-70

|

70

|

99.5

|

92

|

51.5

|

11.3

|

40.0

|

48.7

|

68.7

|

|

TYS1009-75

|

75

|

107

|

97

|

51.5

|

12

|

40.0

|

48.7

|

68.7

|

|

TYS1009-80

|

80

|

112

|

105

|

52

|

14

|

40.0

|

48.0

|

78.0.

|

|

TYS1009-85

|

85

|

120

|

110

|

55

|

14

|

41.0

|

46.0

|

76.0

|

|

TYS1009-90

|

90

|

127

|

115

|

59

|

14

|

45.0

|

51.0

|

76.0

|

|

TYS1009-95

|

95

|

132

|

120

|

60

|

14

|

46.0

|

51.0

|

76.0

|

|

TYS1009-100

|

100

|

137

|

125

|

61

|

14

|

47.0

|

51.0

|

76.0.

|

|

TYS1009-12B

|

12

|

25

|

23

|

21.5

|

6.5

|

15.0

|

26.0

|

33.5

|

|

TYS1009-14B

|

14

|

28.5

|

25

|

23.5

|

6.5

|

17.0

|

28.5

|

33.5

|

English

English 中文简体

中文简体

.png?imageView2/2/format/jp2)