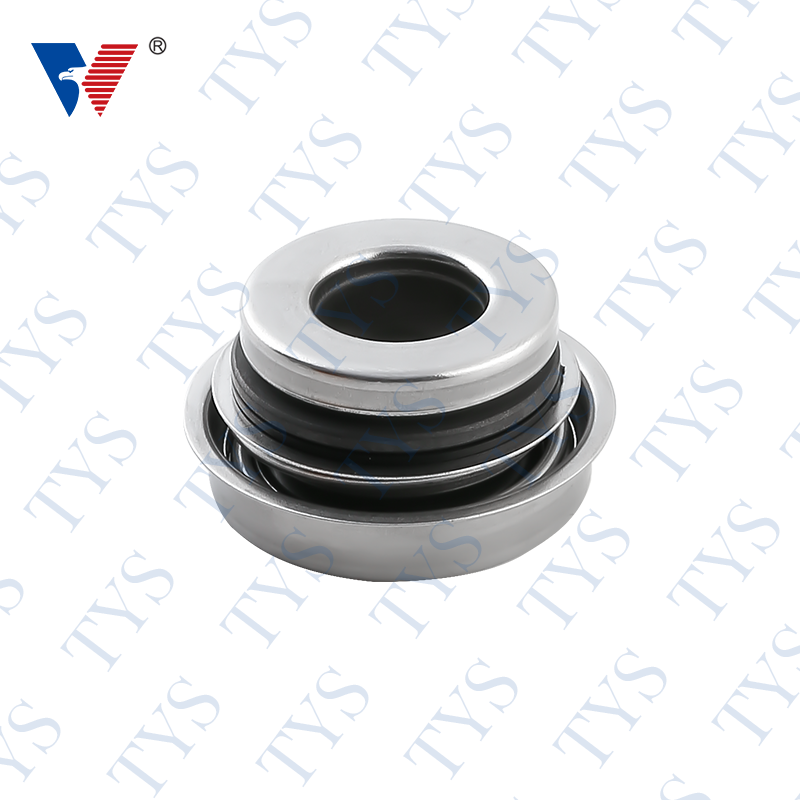

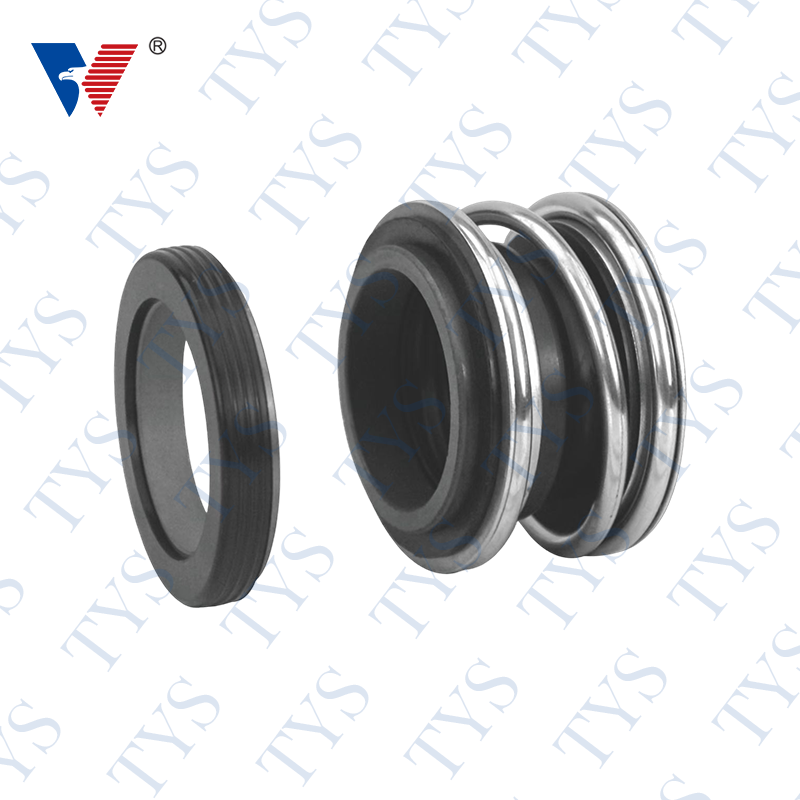

Pump Mechanical Seal

A Pump Mechanical Seal is a mechanical device that prevents fluid leakage in a pump. A mechanical seal consists of two faces that are connected by a rotating shaft. A lubricating liquid is used to maintain contact between the two faces. This fluid also prevents wear and dissipates heat.

In some instances, mechanical seals are installed improperly in pumps. Even a little grit can damage the seal and cause it to fail after only one or two revolutions at pump speed. That's why it is critical to inspect a mechanical seal prior to starting up the pump. You can also consult a seal manufacturer for help with the procedure.

There are two main types of mechanical seals available in the market. The first is the soft packing seal, while the second one is the mechanical seal. Both have their own advantages and disadvantages. Among them, the former has better sealing performance and long service life. However, it has higher cost and requirements. This type of mechanical seal has an average lifespan of more than 12 years.

Pump Mechanical Seals are used in centrifugal pumps and shaft sealing systems. This type of seal has a jacket filled with medium pressure steam. This steam keeps the viscosity of the seal fluid at an acceptable level and helps prevent excessive wear. This seal also features mating faces that make contact with one another and seal the shaft.

When a Pump Mechanical Seal fails, it can cause leakage and cause severe damage to the pump and its other components. Most facilities have procedures to prevent this from happening. Besides, running a pump dry can cause serious damage to the seal. Another factor to consider is the type of fluid being pumped. Some process fluids are hotter than others, and the seal support system may not be up to the task. In addition, when the pump is not lubricated, the pressure is too high and the seal may not be stable.

Depending on the pressure levels, a mechanical seal can either have a static or a dynamic seal. These mechanical seals require proper cooling and lubrication to achieve satisfactory performance. Normally, the lubricant is pumped into the seal chamber. Depending on the pressure difference across the faces of the seal, there is a small amount of leakage. Even the best mechanical seals can experience small leakages.

Surface texturing is another technique that improves the mechanical seal's performance. It reduces friction by 90 percent, and results in longer service life. Further, the resulting stiffer fluid film reduces the face temperature and torque of the seal. Ultimately, this process improves the efficiency of a Pump Mechanical Seal.

Mechanical Seals are important for the integrity of a pump. The material used in a seal must be resistant to high temperatures and abrasives. In addition, a pump's seals need to be lubricated.

|

MODEL

|

d1

|

d3

|

D7

|

L

|

L1

|

L4

|

L2

|

|

TYS301-8

|

8

|

18.0

|

21.0

|

15.0

|

11.0

|

4.5

|

4

|

|

TYS301-10

|

10

|

22.0

|

22.0

|

20.0

|

14.0

|

6.0

|

5

|

|

TYS301-12

|

12

|

24.0

|

26.0

|

21.0

|

13.0

|

6.5

|

6

|

|

TYS301-13

|

13

|

24.0

|

26.0

|

18.5

|

13.0

|

5.5

|

5

|

|

TYS301-14X

|

14

|

26.0

|

26.0

|

21.0

|

13.0

|

6.5

|

6

|

|

TYS301-14d

|

14

|

32.0

|

29.5

|

21.0

|

13.5

|

7.5

|

6

|

|

TYS301-14

|

14

|

28.0

|

30.0

|

21.0

|

13.0

|

6.5

|

6

|

|

TYS301-15

|

15

|

27.5

|

30.0

|

21.0

|

13.0

|

6.5

|

6

|

|

. TYS301-16

|

16

|

27.5

|

30.0

|

21.0

|

13.0

|

6.5

|

6

|

|

TYS301-16d

|

16

|

32.0

|

29.5

|

21.0

|

13.5

|

7.5

|

6

|

|

TYS301-18

|

18

|

39.0

|

42.0

|

21.0

|

13.0

|

8.0

|

6

|

|

TYS301-20

|

20

|

42.0

|

45.0

|

23.0

|

13.0

|

10.0

|

8

|

|

TYS301-25

|

25

|

47.0

|

50.0

|

23.5

|

13.5

|

10.0

|

8

|

|

TYS301-28

|

28

|

54.0

|

57.0

|

25.0

|

15.0

|

10.0

|

8

|

|

TYS301-30

|

30

|

54.0

|

57.0

|

25.0

|

15.0

|

10.0

|

8

|

|

TYS301-17

|

17

|

32.0

|

36.0

|

25.0

|

17.0

|

8.0

|

6

|

|

TYS301-17DY

|

17

|

32.0

|

33.0

|

21.0

|

14.2

|

6.8

|

5.5

|

English

English 中文简体

中文简体

.png?imageView2/2/format/jp2)