The most common type is a single mechanical seal

Author:admin Date:2022-09-22

Inline Pump Seal Types

In order to ensure your Inline Pump functions properly, it is important to understand how an Inline Pump Seal works. It is critical that the seal is working properly because it is a vital component of the pump's overall performance. It may even prevent your pump from failing. Learn more about the Inline Pump Seal here! Let's examine the different types of Inline Pump Seals, including their functions and the benefits of each type.

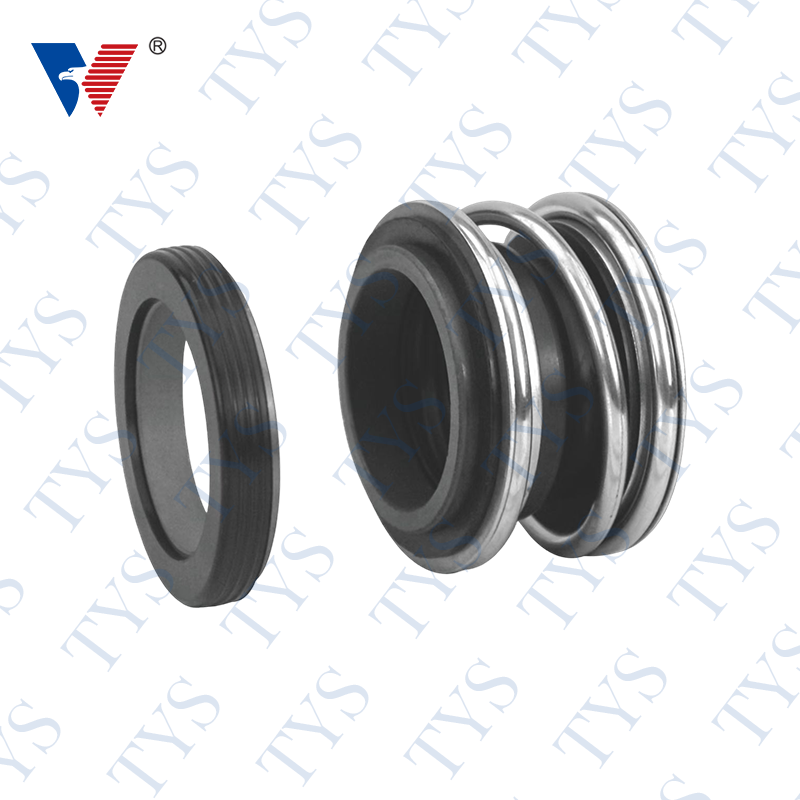

The most common type is a single mechanical seal. It serves as a pump's head seal, preventing liquid from leaking out and air from drawing into the pump when it is under a vacuum. It comprises of several parts, such as a rotating assembly that rotates with the pump shaft. The seal is airtight and compressed by a spring. The pump's shaft also rotates to drive the seal assembly.

When installing an Inline Pump Seal, ensure that it is installed correctly. If the pump seal is not installed properly, you may cause more damage to the pump than it was before. Ensure that the new seal is installed correctly and that you remove any old gasket material. Also, wash your hands before opening the seal kit. If you use bare hands, don't touch the mating parts! And be sure to follow the instructions carefully to ensure the seal works properly.

Another type of Inline Pump Seal is a packed gland. The packed gland is a braided material that is tightly wrapped around the shaft. The shaft is then inserted into a stuffing box. The resulting gas-tight seal prevents the pump from burning. The shaft, however, is subjected to wear and tear over time. The first type of Inline Pump Seal is made of carbon material, while the other type is manufactured of silicone carbide or tungsten carbide.

While centrifugal pumps are the most common, there are several other types of Inline Pump Seal available in the market. While some types are suitable for lower pressures, balanced mechanical seals are preferred for high pressures. Balanced mechanical seals are better for high temperatures because they preserve the heat sensitive components. Choosing the right one is vital for your operation, but you should also consider the type of fluid that will be pumped through the pump.

Inline pumps are an excellent solution for low volume applications. They allow direct connection to pipelines without having to install any extra piping. They can be mounted vertically, horizontally, or on an angle. Because their seal is mechanical, they can be easily serviced without removing the pump's piping. In addition, they are very durable and have a long life span. These pumps are also highly interchangeable with other pumps manufactured by different manufacturers.

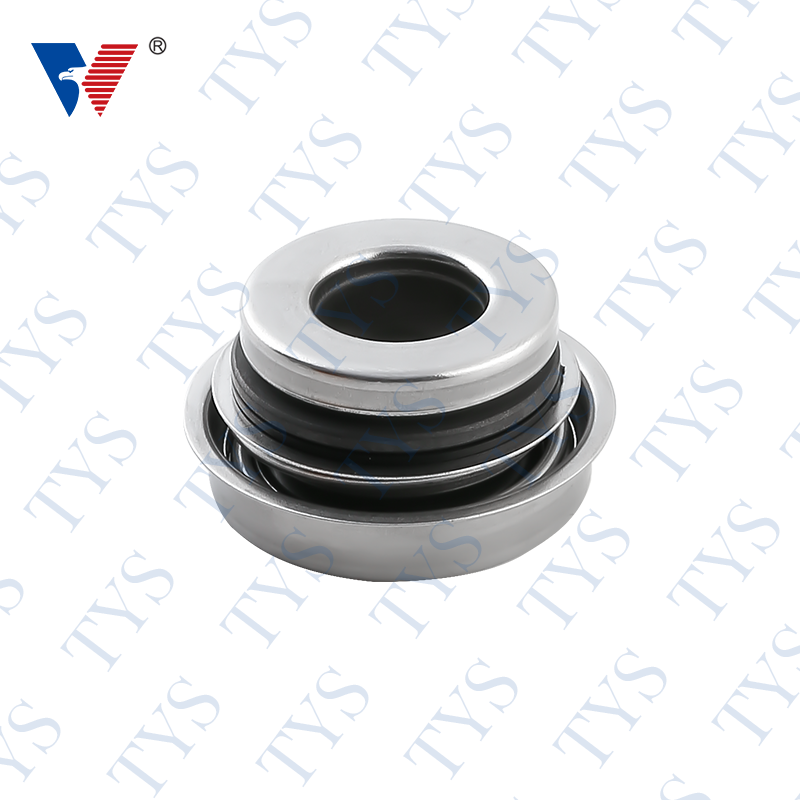

TYS 155 Single spring mechanical seals for water pump seal

Annular Seal Pressure: ≤0Mpa~0.8Mpa

Annular Seal Temperature: -20~ 80℃(-30~200℃)

Rotation speed:≤12m/sec

Medium: Water, Oiland PH numerical value of waste water is 6.5-8

Used in clean water pumps and circulation pumps.

Annular Seal Temperature: -20~ 80℃(-30~200℃)

Rotation speed:≤12m/sec

Medium: Water, Oiland PH numerical value of waste water is 6.5-8

Used in clean water pumps and circulation pumps.

|

MODEL |

d1 |

d3 |

D6 |

D7 |

L |

L1 |

L4 |

|

TYS155-12 |

12 |

22.0 |

16.5 |

20.6 |

23.5 |

18 |

5.5 |

|

TYS155-14 |

14 |

25.0 |

19.0 |

23.1 |

28.0 |

22 |

6.0 |

|

TYS155-15 |

15 |

29.0 |

21.0 |

26.9 |

29.0 |

22 |

.7.0 |

|

TYS155-16 |

16 |

29.0 |

21.0 |

26.9 |

30.0 |

23 |

7.0 |

|

TYS155-17 |

17 |

29.0 |

21.0 |

26.9 |

30.0 |

23 |

7.0 |

|

TYS155-18 |

18 |

33.0 |

25.0 |

30.9 |

32.0 |

24 |

8.0 |

|

TYS155-20 |

20 |

33.0 |

25.0 |

30.9 |

33.0 |

25 |

8.0 |

|

TYS155-22 |

22 |

38.0 |

30.0 |

35.4 |

33.0 |

25 |

8.0 |

|

TYS155-25 |

25 |

40.0 |

33.0 |

38.2 |

35.0 |

27 |

8.5 |

|

TYS155-28 |

28 |

46.0 |

38.0 |

43.3 |

38.0 |

29 |

9.0 |

|

TYS155-30 |

30 |

46.0 |

38.0 |

43.3 |

39.0 |

30 |

9.0 |

English

English 中文简体

中文简体

.png?imageView2/2/format/jp2)