What Is an Industrial Pump Seal?

Author:admin Date:2022-10-08

An Industrial Pump Seal is used in a variety of industrial applications, including pumps, compressors, mixers, and agitators. The selection of the right seal depends on many factors, including the type of fluid, the temperature, and the lubricity and volatility of the liquid or gas being pumped. The pressure applied to the face of the seal also plays a major role in its performance. For example, an unbalanced mechanical seal will perform best in low-pressure applications, while a balanced mechanical seal is best for high-pressure applications. Additionally, the type of chemical and corrosive properties of the fluid can also affect the choice of the proper seal. In addition to these technical considerations, there are also operational safety and emission standards to consider.

If the seal is not properly maintained, it may lead to mechanical failure of the pump. This happens when parts of the pump become faulty, including the impeller and shaft. Other parts of the pump that should be checked include the base, pipes, and bearings. The seal is made up of several parts, including the primary ring, secondary seals, and springs. These components can fail over time if not properly maintained or checked.

The mechanical seal is located behind the impeller on the pump shaft. It is either screwed onto the shaft or is held in place with a bolt. Once removed, the impeller can be easily disassembled to expose the rotary and stationary seal parts. In addition, you can remove the stationary seal parts from the pump's casing and the seal chamber bore.

Mechanical seals consist of two or more optically flat faces that rotate in the same direction. They need to be lubricated to prevent wear. A lubricating liquid provides a thin hydrodynamic film between the seal faces. It also aids heat dissipation. So, in general, mechanical seals are the preferred option when high pressure and volatile liquids are a factor.

A good mechanical seal is essential for the proper operation of a pump. If it is not properly maintained, it can lead to leakage and even catastrophic failure. In addition to keeping a seal in good working order, a properly functioning mechanical seal can improve overall energy efficiency. It can also extend the life of a pump.

Mechanical seals are often made from metal or plastic components and are installed where the shaft enters the pump casing. They prevent leaks in the process and are available in hundreds of different designs. Some are simple and inexpensive while others are complex and expensive. The main purpose of mechanical seals is to keep fluid contained within the pump's casing.

Dual mechanical seals are also available. These seals can last up to five times longer than single mechanical seals in tough conditions. Double mechanical seals also feature metal inner parts that are not exposed to liquid, which makes them ideal for difficult liquids and viscous liquids.

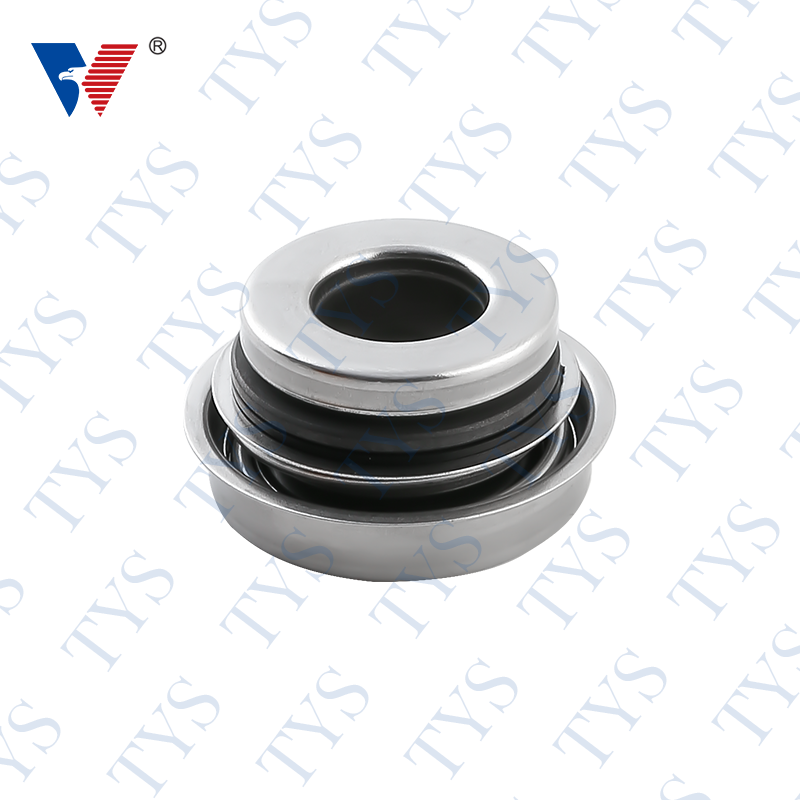

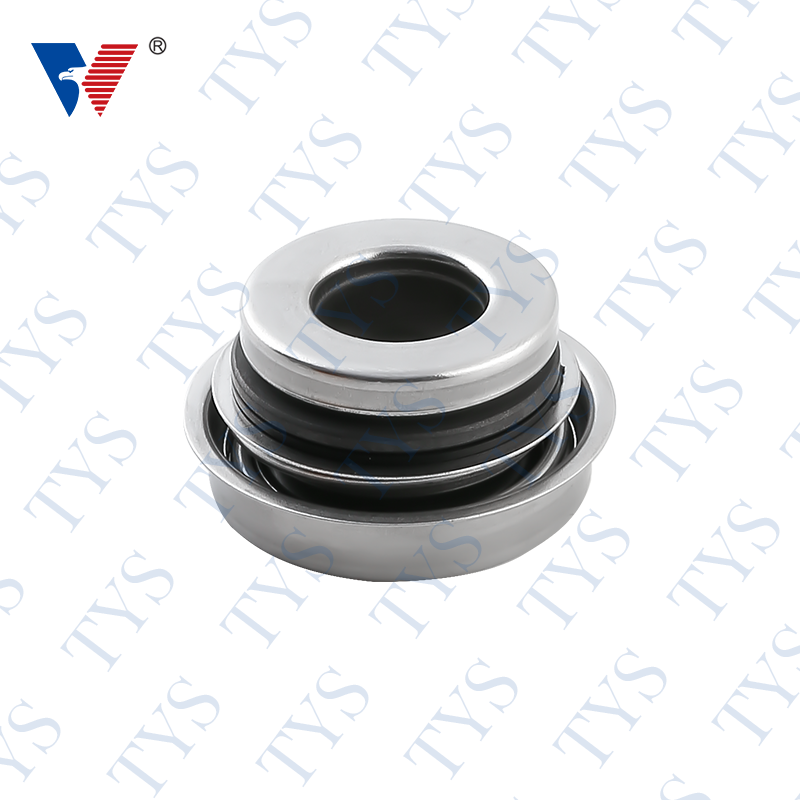

TYS 303C Mechanical Seal Auto Cooling Pump Seal

|

MODEL |

d1 |

D7 |

d3 |

d2 |

L1 |

L2 |

|

TYS303C-10 |

10 |

30.0 |

35.0 |

23.5 |

9.7 |

8.0 |

|

TYS303C-12 |

12 |

28.5 |

35.0 |

25.0 |

9.7 |

8.0 |

|

TYS303C-13 |

13 |

30.0 |

35.0 |

25.0 |

9.7 |

8.0 |

|

TYS303C-15 |

15 |

36.5 |

41.3 |

28.5 |

11.5 |

8.5 |

|

TYS303C-15A |

15 |

30.0 |

35.0 |

28.5 |

11.0 |

8.0 |

|

TYS303C-16 |

15.918 |

36.5 |

41.3 |

28.5 |

10.7 |

8.5 |

|

TYS303C-19 |

19 |

40.0 |

43.7 |

34.8 |

12.5 |

10.0 |

|

TYS303C-20 |

20 |

40.0 |

43.7 |

36.8 |

12.5 |

10.0 |

|

TYS303C-25.4 |

25.4 |

50.0 |

55.0 |

42.0 |

12.5 |

12.5 |

English

English 中文简体

中文简体

.png)