What Is a Vertical Pump Seal?

Author:admin Date:2022-11-10

A simple vertical pump seal has two sealing points: a stationary and rotating face. These faces are held together by flexible "boots" that prevent liquid from leaking around the seal faces. These boots are usually made of elastomer or flexible metal bellows. They can also be made of Teflon.

During operation, the seal is cooled with coolant or clean flush fluid. The seal chamber must be purged before pumping to avoid solids from accumulating. When choosing a vertical pump seal, it is important to consider the effect of the pump and equipment on seal chamber pressure. The pump should be configured with high-point vents to prevent vapors from entering the seal chamber.

A Vertical Pump Seal should be installed in close proximity to the impeller. This will reduce the pressure difference between the suction and discharge. This will help the pump operate more efficiently and reduce operating costs. A high-performance seal with a high radial clearance is ideal for VTPs. Its self-contained design makes installation easy. It is preassembled and preset before shipping. It supports quick and easy impeller adjustments.

A vertical turbine pump is composed of a motor, discharge head, one or more pipe columns, and a pump shaft. Its nozzle is called a discharge nozzle, and the pressure in the seal chamber is equal to the discharge pressure of the pump. In addition, a flush port should be located as high as possible in the vertical turbine pump to prevent excessive pressure inside the vertical turbine pump.

A mechanical seal is important to protect against leaks and contamination. It must have a small gap between the seal faces and be large enough to allow liquid to flow through, but small enough to prevent contaminants from entering. The gap can be as small as 1 micron, which is seventy times thinner than a human hair.

A mechanical seal can also be prone to corrosion. If the liquid is abrasive, it may erode the seal's carbon face. A common way to prevent this is to flush the faces of the seal with clean water. This can be costly, though, as it requires special flushing piping and seals.

Vertical pumps are often found in harsh environments. Their long shafts and considerable radial movement are difficult to seal. In addition, different liquids have different lubricity properties. For instance, a liquid that is abrasive may require a more complex mechanical seal. It's also important to consider the type of liquid that is being pumped.

A vertical turbine pump is an example of a pump that must withstand a lot of pressure and heat to function properly. The shaft must be stable to avoid premature wear of mechanical seals and packing. Depending on the purpose of the pump, selecting a seal with deflection tolerance may be necessary to increase the life of the pump.

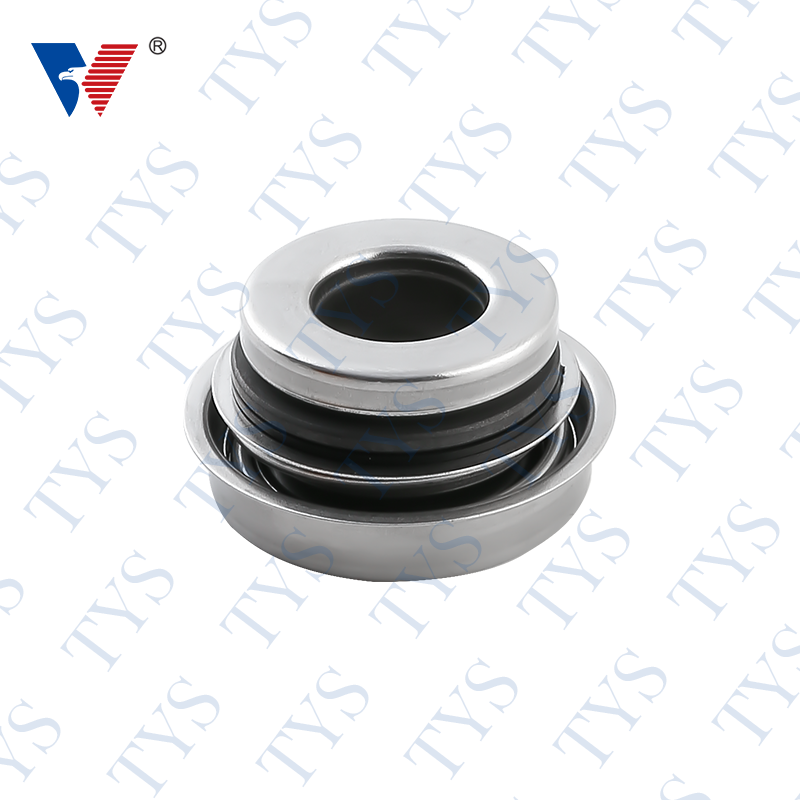

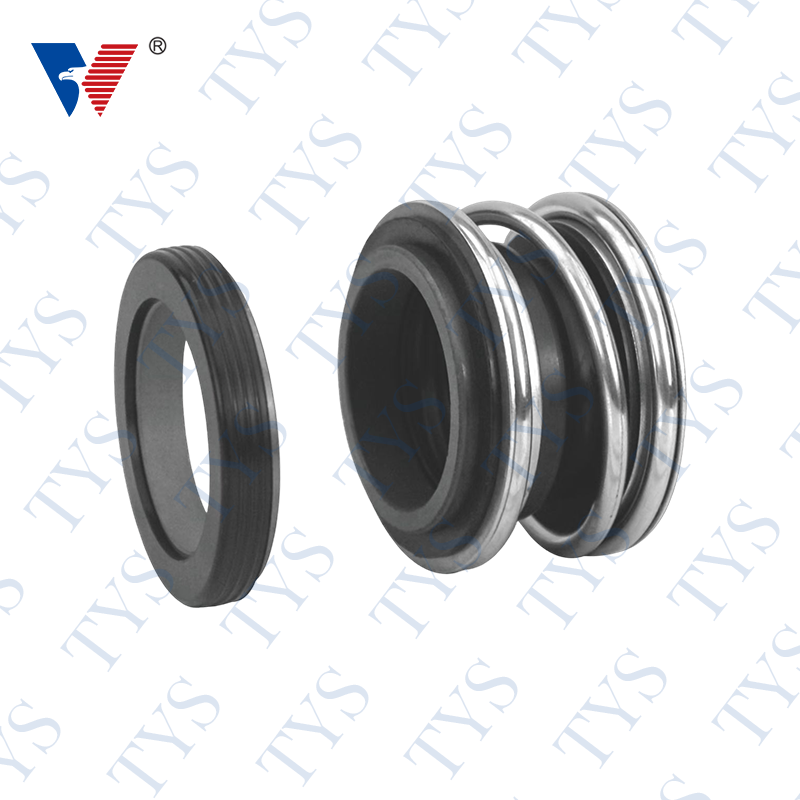

TYS 1007/560/P21 O ring mechanical seal john crane type 1 mechanical seal

|

MODEL |

d1 |

d3 |

D7 |

L |

L1 |

L4 |

L2 |

|

TYS560- 12 |

12 |

26.0 |

26 |

24.0 |

17.5 |

6.5 |

6 |

|

TYS560-14 |

14 |

28.0 |

28 |

25.0 |

18.0 |

7.0 |

6 |

|

TYS560-15 |

15 |

28.0 |

28 |

25.0. |

18.0 |

7.0 |

6 |

|

TYS560-16 |

16 |

30.0 |

32 |

27.0 |

20.0 |

8.0 |

6 |

|

TYS560-18 |

18 |

32.5 |

35 |

27.0 |

19.0 |

8.0 |

6 |

|

TYS560-19 |

19 |

32.5 |

35 |

27.0 |

18.0 |

8.0 |

6 |

|

TYS560-20 |

20 |

35.5 |

38 |

28.0 |

19.5 |

8.0 |

6 |

|

TYS560-22 |

22 |

37.5 |

40 |

28.0 |

20.0 |

8.0 |

6 |

|

TYS560-25 |

25 |

42.0 |

44 |

29.0 |

20.0 |

9.0 |

7 |

|

TYS560-28 |

28 |

45.5 |

46 |

30.0 |

21.0 |

9.0 |

7 |

|

TYS560-30 |

30 |

48.0 |

50 |

31.0 |

22.0 |

9.0 |

7 |

|

TYS560-32 |

32 |

50.0 |

54 |

33.0 |

24.0 |

9.0 |

7 |

|

TYS560-35 |

35 |

54.5 |

58 |

36.0 |

26.0 |

10 |

8 |

|

TYS560-38 |

38 |

58.5 |

60 |

37.0 |

27.0 |

10 |

8 |

|

TYS560-40 |

40 |

62.5 |

64 |

38.0 |

28.0 |

10 |

8 |

|

TYS560-45 |

45 |

66.5 |

66 |

40.0 |

30.0 |

10 |

8 |

|

TYS560-50 |

50 |

72.5 |

72 |

42.0 |

32.0 |

10 |

8 |

English

English 中文简体

中文简体

.png?imageView2/2/format/jp2)