How to Prevent Leakage From a Submersible Pump Seal

Author:admin Date:2023-01-28

Submersible pump seals are important components of a submersible pump, and a faulty seal can lead to a deteriorating pump. A damaged seal can cause leakage, which can lead to contamination in the pump, and can lead to a decrease in overall equipment life. Fortunately, there are ways to prevent leakage, and to improve the life of a seal.

First, it is vital to understand the types of mechanical seals used in submersible pumps. There are several different kinds, each with unique characteristics, but they all perform the same basic function. By identifying the type of seal, you can select the most appropriate one for your pumping application.

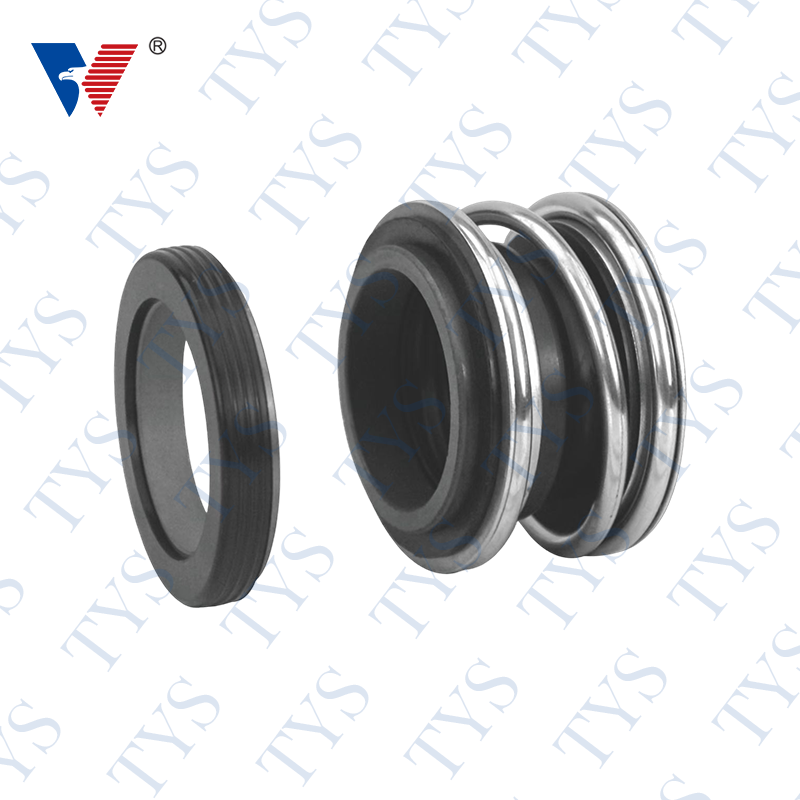

Mechanical seals have two faces. The first face is fixed to the shaft, and the second face is flexible. This face is pressed into the shaft by a spring. It may be sealed in place with an o-ring, or it may be a gasket. These faces should be cleaned with solvent or dust free paper.

Depending on the type of seal, you will need to determine the material that you use for the mechanical seal. Silicon carbide, for example, is the preferred material for modern submersible pumps. However, this material is expensive and has to be upgraded for corrosive environments. If you are not sure what to choose, check with your manufacturer for recommendations.

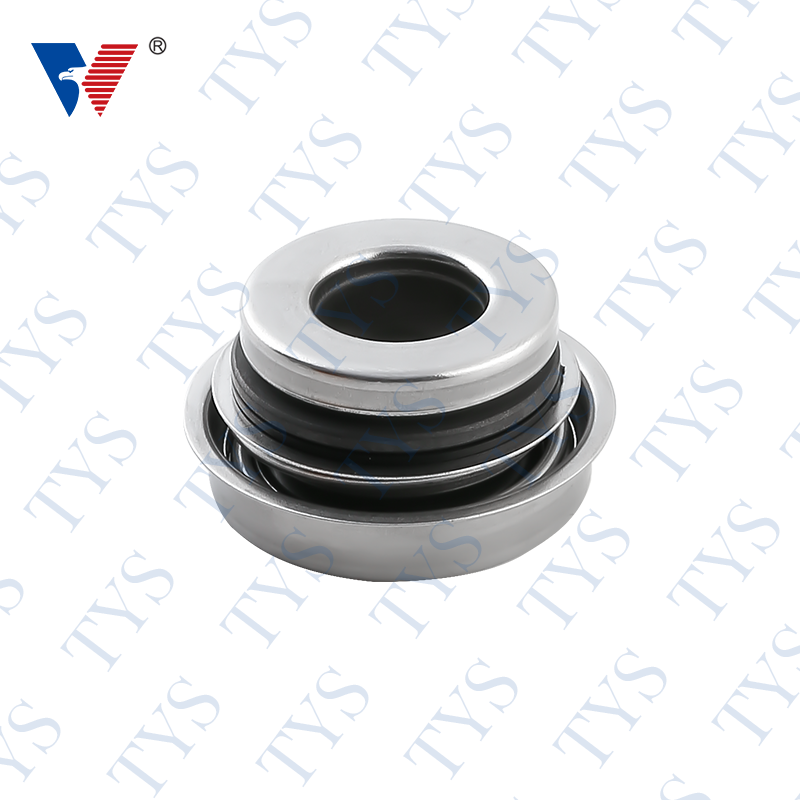

Some submersible pump seals include the following parts: a seal-chamber section, a primary mechanical seal, and a secondary oil seal. In addition, a number of seal assemblies may be connected in series. Depending on the design, the motor can be coupled to the seal assembly.

For example, an electric submersible pump assembly is comprised of a pump, a motor, and a seal-chamber section. Typically, the seal-chamber section is below the motor and includes the primary mechanical seal, the secondary oil seal, and the pressure equalizing device. An auxiliary seal is also part of the seal-chamber section.

Seal-chamber sections typically have a main or static ring. The secondary sealing surface is usually an auxiliary rubber or V-ring. When a pump is operating in a medium with strong acids and alkalis, the auxiliary seal can corrode. Additionally, weak acid can cause excessive mechanical leakage.

A variety of materials are used to make secondary seal faces. One company used type 420 stainless steel to minimize shaft deflection. Others have found that the proper shaft-length to shaft-diameter ratio helps to minimize deflection.

If your seal is worn out, you should replace it. You can do this by contacting the manufacturer or a qualified technician. As with any replacement, make sure to follow the manufacturer's instructions for the seal.

If you are using a submersible pump, you should consider a seal-chamber section that has a diameter of no more than 7 times the shaft diameter. This will minimize the likelihood of deflection, and reduce the risk of leakage. Ideally, the seal-chamber section should have axial movement less than 0.1mm.

English

English 中文简体

中文简体

.png?imageView2/2/format/jp2)