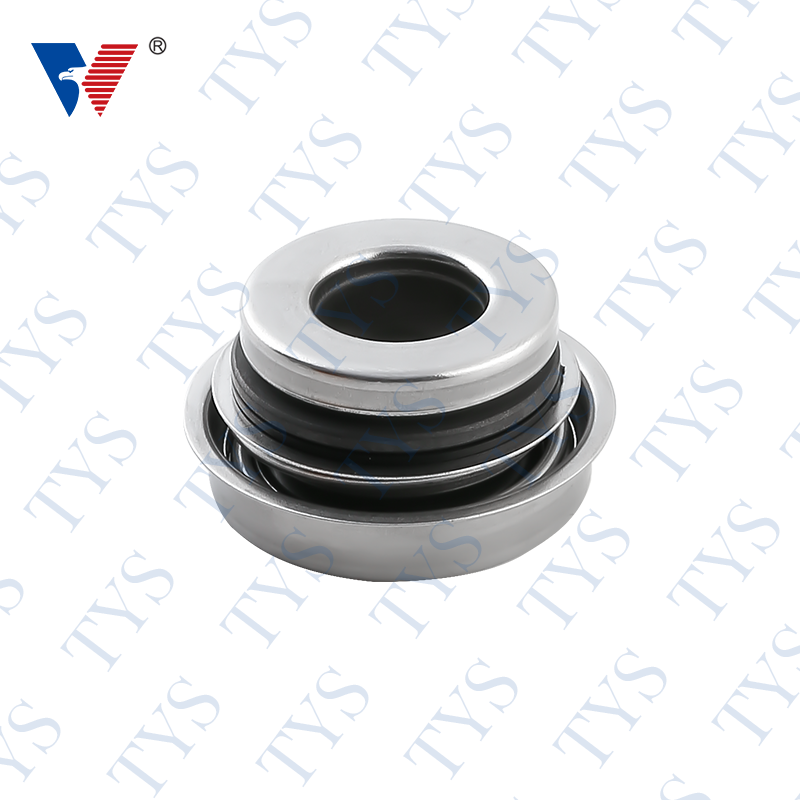

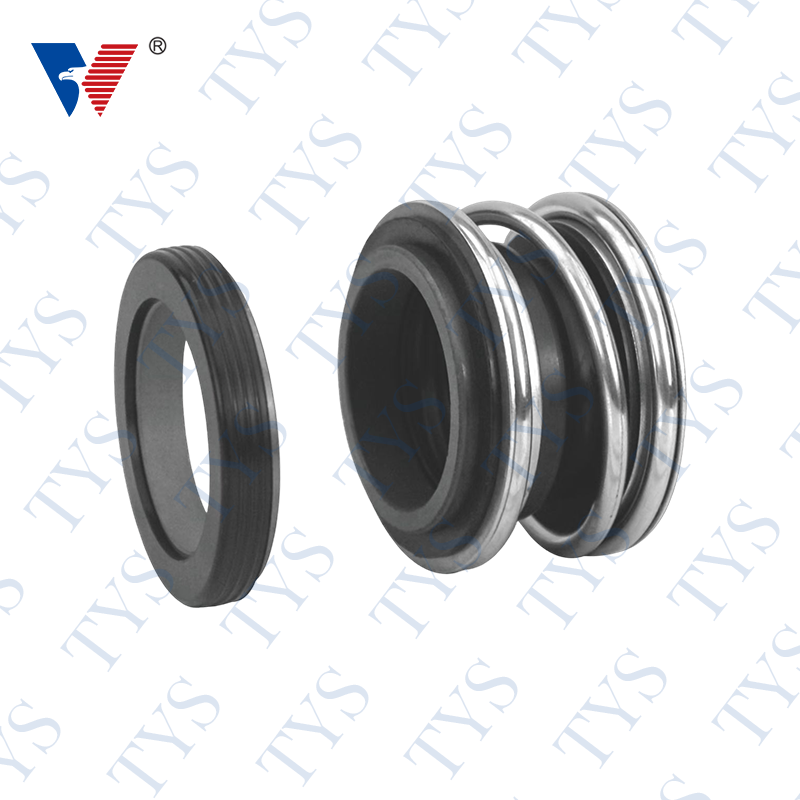

An MG1 Mechanical Seal is one of the most common types of seals

|

MODEL |

d1 |

d3 |

D7 |

L |

L28 |

MG1 |

MG12 |

MG13 |

|

TYS1009-12 |

12 |

25 |

26 |

21.5 |

6.5 |

/ |

/ |

/ |

|

TYS1009-14 |

14 |

28.5 |

28 |

23.5 |

6.5 |

/ |

/ |

/ |

|

TYS1009-16 |

16 |

28.5 |

27 |

23.5 |

6.5 |

17.0 |

28.5 |

33.5 |

|

TYS1009-18 |

18 |

32 |

33 |

27 |

6.5 |

19.5 |

30.0 |

37.5 |

|

TYS1009-20 |

20 |

37 |

35 |

29 |

6.5 |

21.5 |

30.0 |

37.5 |

|

TYS1009-22 |

22 |

37 |

37 |

29 |

7.5 |

21.5 |

30.0 |

37.5 |

|

TYS1009-25 |

25 |

42.5 |

40 |

31 |

7.5 |

23.0 |

32.5 |

42.5 |

|

TYS1009-28 |

28 |

49 |

43 |

34 |

7.5 |

26.5 |

35.0 |

42.5 |

|

TYS1009-30 |

30 |

49 |

45 |

34 |

7.5 |

26.5 |

35.0 |

42.5. |

|

TYS1009-35 |

35 |

57 |

50 |

36 |

9 |

28.5 |

35.0 |

47.5 |

|

TYS1009-40 |

40 |

62 |

58 |

36 |

9 |

30.0 |

36.0 |

46.0 |

|

TYS1009-45 |

45 |

68 |

63 |

39 |

9.5 |

30.0 |

36.0 |

51.0 |

|

TYS1009-50 |

50 |

74 |

70 |

39 |

11 |

30.0 |

38.0 |

50.5. |

|

TYS1009-55 |

55 |

81 |

75 |

46 |

11 |

35.0 |

36.5 |

59.0 |

|

TYS1009-60 |

60 |

85.5 |

80 |

49 |

11 |

38.0 |

41.5 |

59.0 |

|

TYS1009-65 |

65 |

93.5 |

85 |

51 |

11.3 |

40.0 |

41.5 |

69.0 |

|

TYS1009-70 |

70 |

99.5 |

92 |

51.5 |

11.3 |

40.0 |

48.7 |

68.7 |

|

TYS1009-75 |

75 |

107 |

97 |

51.5 |

12 |

40.0 |

48.7 |

68.7 |

|

TYS1009-80 |

80 |

112 |

105 |

52 |

14 |

40.0 |

48.0 |

78.0. |

|

TYS1009-85 |

85 |

120 |

110 |

55 |

14 |

41.0 |

46.0 |

76.0 |

|

TYS1009-90 |

90 |

127 |

115 |

59 |

14 |

45.0 |

51.0 |

76.0 |

|

TYS1009-95 |

95 |

132 |

120 |

60 |

14 |

46.0 |

51.0 |

76.0 |

|

TYS1009-100 |

100 |

137 |

125 |

61 |

14 |

47.0 |

51.0 |

76.0. |

|

TYS1009-12B |

12 |

25 |

23 |

21.5 |

6.5 |

15.0 |

26.0 |

33.5 |

|

TYS1009-14B |

14 |

28.5 |

25 |

23.5 |

6.5 |

17.0 |

28.5 |

33.5 |

English

English 中文简体

中文简体

.png?imageView2/2/format/jp2)