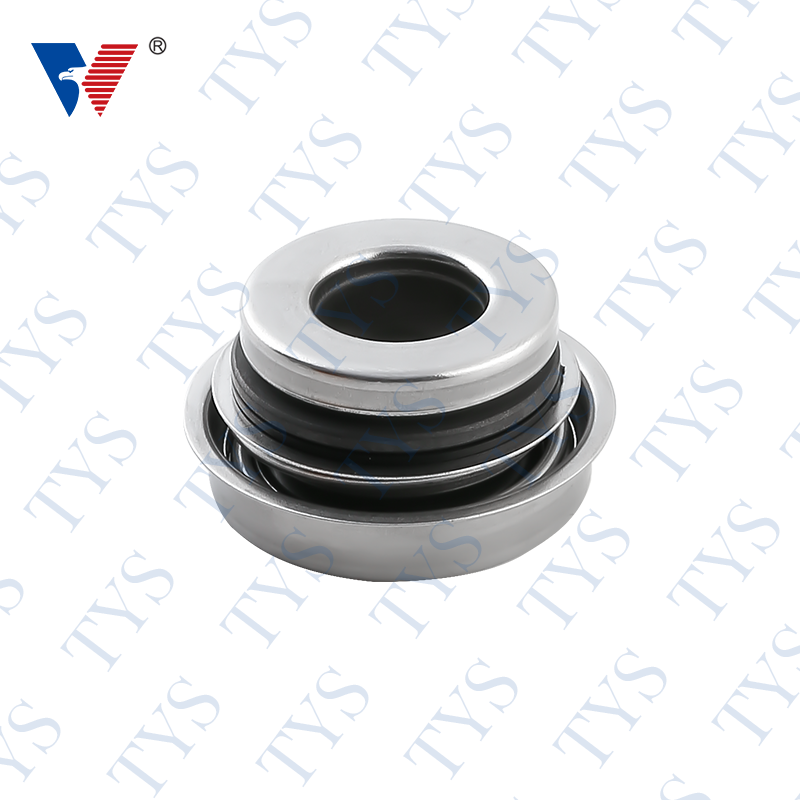

A vertical pump seal (VPS) is a mechanical seal that physically seals a pump between two rotating parts

Author:admin Date:2023-05-10

What Is a Vertical Pump Seal?

The Vertical Pump Seal (VPS) is a mechanical seal that physically seals the pump between two rotating parts. The mechanical seal's rotating face is attached to the pump's shaft. Because the seal's face is in contact with the pump when it is at rest, it requires lubrication. The lubricant helps prevent fluid leakage by forming a thin hydrodynamic film between the two faces.

The mechanical seal can be easily flushed by rinsing it with flushing fluid. Flushing the seal with fluid will remove heat and vapors from the mechanical seal chamber. It is important to choose a flushing fluid that is non-polymeric and moderate in temperature.

While the liquid seal is effective in preventing product leakage, it is not infallible. Occasionally, it leaks a tiny amount of liquid from the pump. The amount is negligible but can accumulate over time. This causes secondary problems such as extra cleaning and disposal costs. Gaskets, on the other hand, are more forgiving than mechanical seals. This makes them suitable for applications involving excessive wear and tear.

The material used in Vertical Pump Seals should be resistant to both high and low temperatures. The liquid can drop to 32 F, or rise to 212 F. Viton and EPR elastomers are recommended for low-temperature applications. Silicon carbide can be used instead of standard ceramic faces. However, ceramic faces are very vulnerable to thermal shock, and any sudden change in temperature can shatter them. So, it is best to purchase a higher-quality Vertical Pump Seal to ensure that it is reliable.

Proper maintenance is essential to achieving optimal performance. Proper flushing and cooling will minimize the wear and tear on the seal. The seal can be lubricated with clean water, but may also need a specialized barrier fluid for best results. In addition, shaft deflection may lead to wear and tear, so end users should select a seal that will tolerate the deflection.

Proper maintenance of the seal will ensure optimal pump performance. Proper mechanical seals are the first step toward keeping the machinery safe. Proper maintenance will also help reduce friction and heat. Proper maintenance will prevent costly product leakage and degraded pumps. It is also necessary to consider the safety of the operators as it relates to the seal.

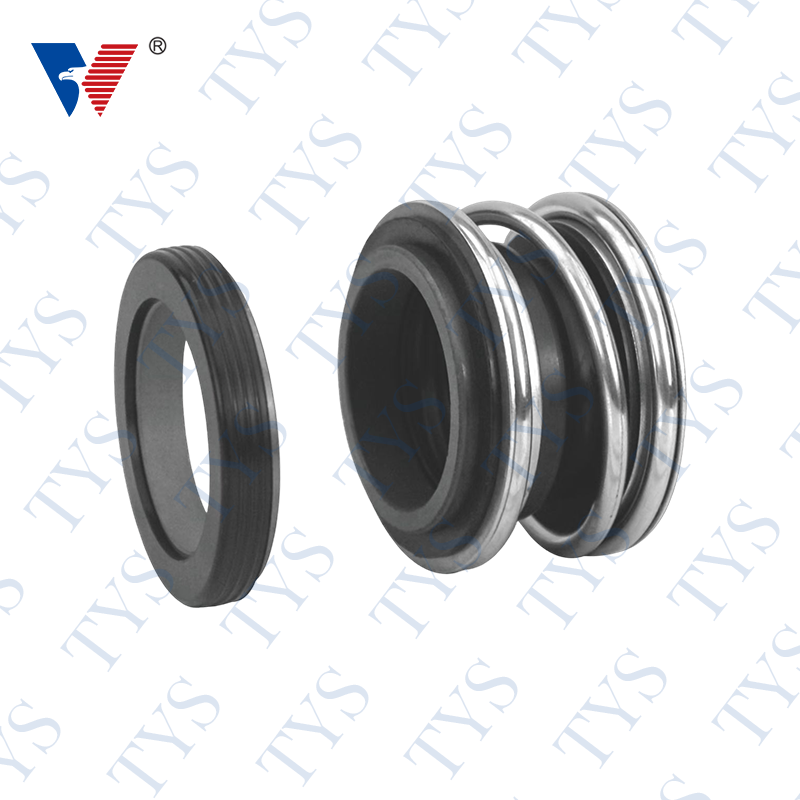

TYS 155 Single spring mechanical seals for water pump seal

Annular Seal Pressure: ≤0Mpa~0.8Mpa

Annular Seal Temperature: -20~ 80℃(-30~200℃)

Rotation speed:≤12m/sec

Medium: Water, Oiland PH numerical value of waste water is 6.5-8

Used in clean water pumps and circulation pumps.

English

English 中文简体

中文简体

.png?imageView2/2/format/jp2)