How to Choose an Industrial Pump Seal

Author:admin Date:2022-12-28

When it comes to choosing a pump seal, there are many factors to consider. You must consider the nature of the fluid, its temperature, and the pressure to be sealed. These parameters determine the type of seal that is best suited for the application. Choosing the right seal for your needs can help to ensure that your pump continues to function properly.

The material used to make the mechanical seal can have a profound effect on its ability to perform its job. Seals made from rubber are commonly found in automotive applications and in chemical industries. Whether you're looking for a new seal or one to repair an existing unit, it's important to find a seal vendor that can provide you with the most up-to-date information.

Several types of industrial pump seals are available. Some are simple, while others are complex. Regardless of the type you choose, it's essential to install the seal according to the manufacturer's installation instructions. Even a small mistake can result in serious damage to the seal. If you don't perform the required maintenance, you could be risking the safety of your equipment and your workforce.

While the mechanical seal may be an attractive option for some, it is important to remember that there are several different ways for the fluid to leak. This includes leakage from the mechanical seal itself, from the shaft or casing, or from a component that is not directly related to the seal.

One of the most effective methods to prevent leaks is by installing a secondary fluid. A barrier fluid that is not pumped through the pump helps to absorb friction heat that is generated during the sealing process. A secondary fluid also improves the safety of the pump and allows the pumped fluid to cool without contacting the ambient air.

It is a good idea to install a barrier fluid that is a couple of bar higher than the highest pressure that you will be sealing. This will prevent any ambient air from contacting the pumped fluid.

Another effective method of pumping is to use a fan impeller mounted on the shaft. The impeller intensifies the convection. Depending on your requirements, you can even install a heat exchanger. However, not all pumps require this approach.

One of the easiest ways to detect a leak is to inspect the mechanical seal itself. If the seal appears to be damaged, it may be time to consider upgrading to a more efficient model. If you do decide to replace the seal, contact a trained seal expert to help you determine which seals you'll need and which types will meet your specifications.

Lastly, it's always a good idea to choose a mechanical seal that is compatible with the equipment that you're using. Pumps that are used in chemical or refining plants often work with various kinds of fluids. Having a seal that is designed to handle these fluids can be beneficial.

Mechanical seals are available in hundreds of different styles. They vary in price and complexity. Choose a seal vendor that can assist you in selecting the optimal design and support setup for your industrial pump.

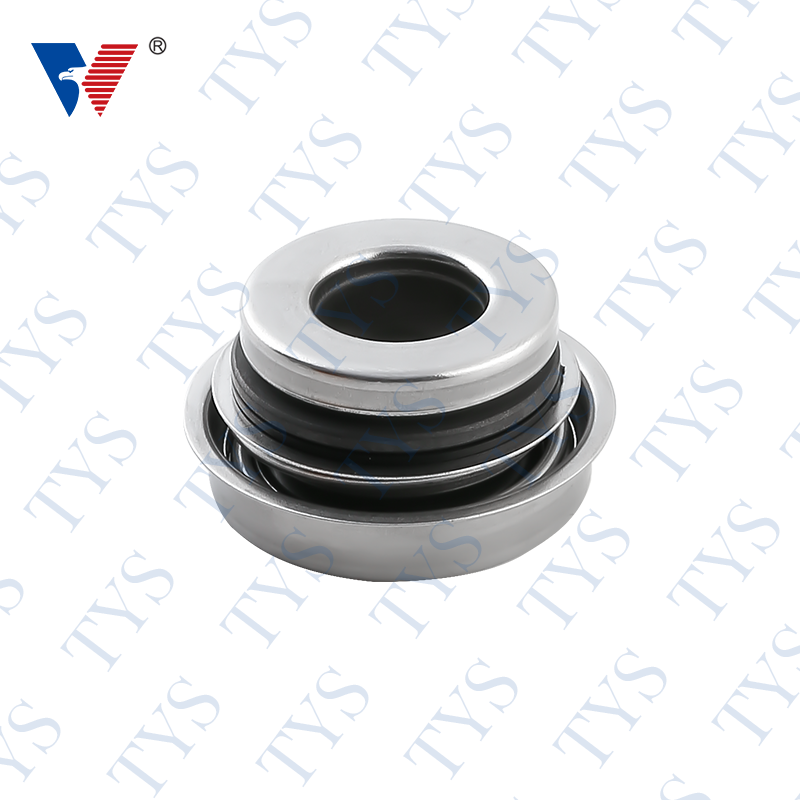

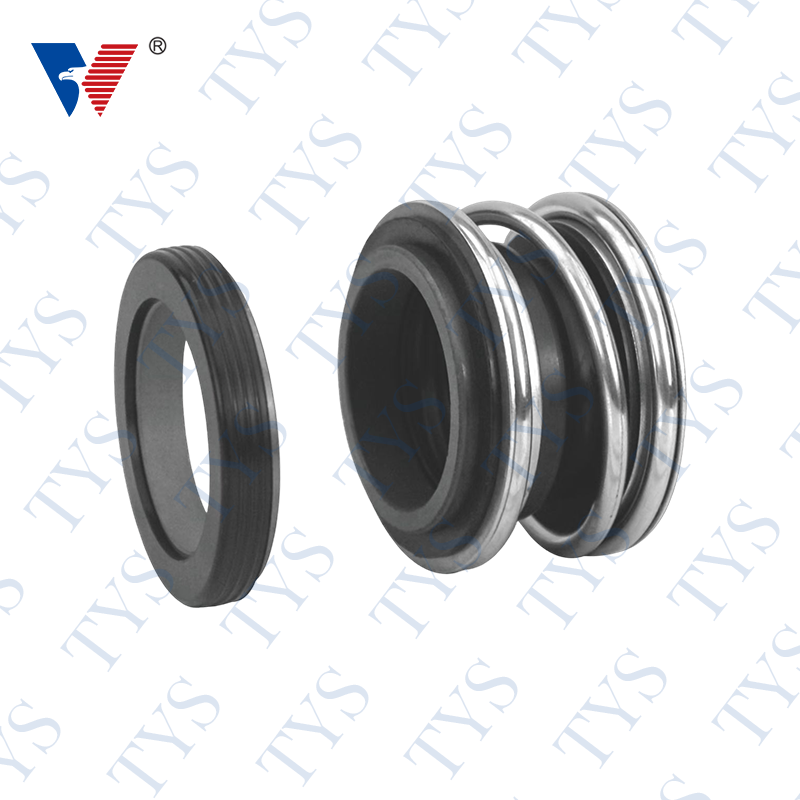

TYS 155 Single spring mechanical seals for water pump seal

|

MODEL |

d1 |

d3 |

D6 |

D7 |

L |

L1 |

L4 |

|

TYS155-12 |

12 |

22.0 |

16.5 |

20.6 |

23.5 |

18 |

5.5 |

|

TYS155-14 |

14 |

25.0 |

19.0 |

23.1 |

28.0 |

22 |

6.0 |

|

TYS155-15 |

15 |

29.0 |

21.0 |

26.9 |

29.0 |

22 |

.7.0 |

|

TYS155-16 |

16 |

29.0 |

21.0 |

26.9 |

30.0 |

23 |

7.0 |

|

TYS155-17 |

17 |

29.0 |

21.0 |

26.9 |

30.0 |

23 |

7.0 |

|

TYS155-18 |

18 |

33.0 |

25.0 |

30.9 |

32.0 |

24 |

8.0 |

|

TYS155-20 |

20 |

33.0 |

25.0 |

30.9 |

33.0 |

25 |

8.0 |

|

TYS155-22 |

22 |

38.0 |

30.0 |

35.4 |

33.0 |

25 |

8.0 |

|

TYS155-25 |

25 |

40.0 |

33.0 |

38.2 |

35.0 |

27 |

8.5 |

|

TYS155-28 |

28 |

46.0 |

38.0 |

43.3 |

38.0 |

29 |

9.0 |

|

TYS155-30 |

30 |

46.0 |

38.0 |

43.3 |

39.0 |

30 |

9.0 |

English

English 中文简体

中文简体

.png?imageView2/2/format/jp2)